Volume 4, Issue 2 (Spring 2015 2015)

J Occup Health Epidemiol 2015, 4(2): 116-124 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Beheshti M, Boroumand Nejad E, Bahalgerdy B, Mehrafshan F, Zamani Arimy A. Performance loss among workers due to heat stress in high-temperature workplaces. J Occup Health Epidemiol 2015; 4 (2) :116-124

URL: http://johe.rums.ac.ir/article-1-159-en.html

URL: http://johe.rums.ac.ir/article-1-159-en.html

Related article in

Google Scholar

Google Scholar

Similar articles

1- Faculty Member, Dept. of Occupational Health, Faculty of Health, Gonabad University of Medical Sciences, Gonabad, Iran.

2- Dept. of Occupational Health, Faculty of Health, Gonabad University of Medical Sciences, Gonabad, Iran.

3- Dept. of Occupational Health, Faculty of Health, Gonabad University of Medical Sciences, Gonabad, Iran. ,fatemehmehrafshan@yahoo.com

2- Dept. of Occupational Health, Faculty of Health, Gonabad University of Medical Sciences, Gonabad, Iran.

3- Dept. of Occupational Health, Faculty of Health, Gonabad University of Medical Sciences, Gonabad, Iran. ,

Article history

Received: 2014/07/8

Accepted: 2015/03/28

ePublished: 2015/06/29

Accepted: 2015/03/28

ePublished: 2015/06/29

Subject:

Occupational Health

Full-Text [PDF 574 kb]

(3847 Downloads)

| Abstract (HTML) (8132 Views)

Table1: Occupational permissible exposure limit for heat stress exposure based on wet-bulb globe temperature (WBGT) index (

.jpg)

Figure1: The relationship between work capacity and wet-bulb globe temperature(WBGT) with respect to four intensities

.jpg)

Figure2. Thermal stress and its consequent performance loss in bakeries

Table 2: Results of heat stress evaluation in bakeries around the city of Gonabad, Iran, in spring 2014 (℃)

Full-Text: (150 Views)

Introduction

Heat is recognized as a harmful physical factor in many workplaces. Thermal stress due to heat is caused by a number of internal and external thermal factors which lead to fatigue and development of disease in the human body (1). Environmental heat influences the performance and productivity of humans through changing physiological parameters, such as blood flow and hormone release rate. Moreover, the global warming phenomenon can also reduce productivity; increase the prevalence of diseases and its related health costs, immigration, natural disasters, and etcetera. When people perform physical activities in hot environments, they are at risk of increase in deep body temperature (more than 38°C), decrease the physical work capacity and mental capacity, increase in accident frequency, and ultimately, heat exhaustion and heat stroke (2). In the same vein, the results of epidemiological studies and work reports in Taiwan showed the notable impact of warm weather onsome infectious diseases, such as dengue fever. However, hot climate can also influence the health of workers and labor productivity, especially in older people who are more prone to such impacts.

In addition to the aforementioned complications, extreme heat stress in workers can in some cases lead to death. Currently, the number of deaths caused by workplace heat stress in the United States and Canada has amounted to 22 individuals per year. The Toronto Health Department estimates that this number will increase from 20 in 2001 to 300 cases in 2020 (3). The study by Kjellstrom et al. showed that in countries with extremely hot seasons, labor forces are required to work in environments where temperature conditions are warmer than standard conditions for the suitable functioning of the physiological mechanism of the human body (2). The excessive increase in workplace temperature will aggravate mental stress, reduce work capacity, and decrease productivity (4, 5). In addition to its health related consequences, exposure to heat can deteriorate human performance under various conditions (6). It has been reported in the National Institute of Occupational Safety and Health (NIOSH) standard that high wet-bulb globe temperature (WBGT) level will hamper workers’ performancein their assigned tasks(7, 8). A natural human reaction to heat stress is lowering physical activity, which is intended asa strategy to reducecore body heat (2). This preventive reaction reduces the work capacity of individuals. Thus, the effect of excessive heat exposure on work capacity is a natural protective reaction that aims to reduce the risk of heat stroke by reducing the pace of work (2). Hubler et al. in their study on the effects of climate change in Germany found that, based on empirical studies on its health effects, it can increase the mortality rate and health costs of heat stress by 3 and 6 times, respectively (9).

The main factor underlying these effects is increased deep body temperature along with dehydration resulting from inadequate water consumption. Excessive dehydration may result in marked fatigue and clinical diseases, especially renal failures (2). There is a wide range of health effects caused by climate change, including direct impacts, such as changing temperature and comfort of individuals,and indirect effects,such as greater frequency of storms, floods, infectious disease, food poisoning, and insect-induced and plant-induced allergies (9). Heat stress can be associated with psychological and physical effects such as irritability, nervousness, moodiness, depression (mental effects), cardiovascular complications, perspiration, water and electrolyte imbalance, and changes in blood flow rate (physical effects). A combination of mental and physical reactions is embodied in the form of low work efficiency, reduced labor skills, muscular fatigue, poor concentration, and thus, increased frequency of mistakes.

Environmental heat may lead to increased thermal load inside and outside the workplace, thereby decreasing the productivity of millions of workers (6). In general, productivity refers to the extent of efficiency in achieving the objectives of the system and is generally defined as the ratio of input to output (5). Workers in the construction industry, farmers, and fishermen may suffer from the thermal effects of climate change on productivity (10). To compensate for the loss of productivity due to heat stress, workers may be required to work longer hours or employers may be obliged to hire extra labor forces (6). In middle and low income countries, given the undesirable workplace conditions for both outdoor and indoor environments, productivity is often low (6). Currently, there is a paucity of research about the effects of heat stress on the performance and productivity of humans.Moreover, the existing data on the real exposure of workers to high-temperature environments and reduced productivity and efficiency are rather ambiguous (10). If the necessary control measures are not taken, high workplace temperature may have considerable effects on productivity, occupational efficiency, and their related costs. The aim of this study was to evaluate thermal stress and performance loss caused by high-temperature indoor work environments in Gonabad, Iran.

It should be noted that this study is the first of its type in Iran.Thus, its results can be incorporated in future studies to help prepare systematic plans for the protection of workers against this problem.

Material and Methods

This descriptive-analytical study was conducted on indoor high-temperature workplaces in the city of Gonabad. Consistent with the available literature, the stratified sampling method was used in the present in which each business unit or profession was considered as a stratum. Then, in proportion to the size of each stratum, a number of units were selected randomly. In this study, 15 bakeries, including 3 Barbari, 4 Sangak, and 8 Lavash bread baking bakeries, 11restaurants and kitchens, and 2 high-temperature industries including refractory brick manufacturing and porcelain industries all of which are enclosed or indoor high-temperature jobs, were examined. In total, 1450 individuals worked on the investigated sites and were exposed to thermal stress. Since in this study measurement of heat stress was conductedthrough public and environmental method, personnel demographic characteristics, such as age and sex,were not considered as intervening factors. The inclusion criterion for this study was workingin an environment that included a heating process and the exclusion criterion was unwillingness to participate in the study.All individuals and managers were informed of the aims of the project and were assured of the confidentialityof data. The WBGT index was used to measure heat stress.

WBGT-meter device (Model MK427JY,Casella Company in Australia) was used to measure environmental parameters such as dry temperature, wet temperature, and radiant temperature in the 3 positions of the workers’ head (1.7 m), body (1.1 m), and ankle (0.1m), respectively.Measurements were performed at 3 heights because the level of heat stress varied at different heights, on average, more than 3 °C, especially in bakeries.

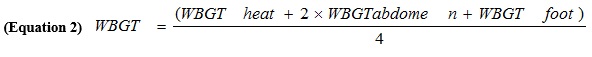

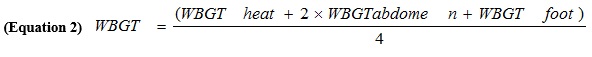

Considering that in indoor work environments, usually heat exchange takes place entirely during 45minutes, in all measurements, the thermometers were placed in the desired site for 45 minutes and the final temperature was recorded. Using the NIOSH equation (Equation 2), the mean value of this index was determined at workplaces for each worker. The values of WBGT heat stress index and standard threshold limit value (TLV) of heat stress were compared with respect to the type of work, working time, and rest periods.

.jpg)

WhereTnw is the natural wet-bulb temperature and Tg is the globe thermometer temperature, and temperatures may be in either Celsius or Fahrenheit.

Heat is recognized as a harmful physical factor in many workplaces. Thermal stress due to heat is caused by a number of internal and external thermal factors which lead to fatigue and development of disease in the human body (1). Environmental heat influences the performance and productivity of humans through changing physiological parameters, such as blood flow and hormone release rate. Moreover, the global warming phenomenon can also reduce productivity; increase the prevalence of diseases and its related health costs, immigration, natural disasters, and etcetera. When people perform physical activities in hot environments, they are at risk of increase in deep body temperature (more than 38°C), decrease the physical work capacity and mental capacity, increase in accident frequency, and ultimately, heat exhaustion and heat stroke (2). In the same vein, the results of epidemiological studies and work reports in Taiwan showed the notable impact of warm weather onsome infectious diseases, such as dengue fever. However, hot climate can also influence the health of workers and labor productivity, especially in older people who are more prone to such impacts.

In addition to the aforementioned complications, extreme heat stress in workers can in some cases lead to death. Currently, the number of deaths caused by workplace heat stress in the United States and Canada has amounted to 22 individuals per year. The Toronto Health Department estimates that this number will increase from 20 in 2001 to 300 cases in 2020 (3). The study by Kjellstrom et al. showed that in countries with extremely hot seasons, labor forces are required to work in environments where temperature conditions are warmer than standard conditions for the suitable functioning of the physiological mechanism of the human body (2). The excessive increase in workplace temperature will aggravate mental stress, reduce work capacity, and decrease productivity (4, 5). In addition to its health related consequences, exposure to heat can deteriorate human performance under various conditions (6). It has been reported in the National Institute of Occupational Safety and Health (NIOSH) standard that high wet-bulb globe temperature (WBGT) level will hamper workers’ performancein their assigned tasks(7, 8). A natural human reaction to heat stress is lowering physical activity, which is intended asa strategy to reducecore body heat (2). This preventive reaction reduces the work capacity of individuals. Thus, the effect of excessive heat exposure on work capacity is a natural protective reaction that aims to reduce the risk of heat stroke by reducing the pace of work (2). Hubler et al. in their study on the effects of climate change in Germany found that, based on empirical studies on its health effects, it can increase the mortality rate and health costs of heat stress by 3 and 6 times, respectively (9).

The main factor underlying these effects is increased deep body temperature along with dehydration resulting from inadequate water consumption. Excessive dehydration may result in marked fatigue and clinical diseases, especially renal failures (2). There is a wide range of health effects caused by climate change, including direct impacts, such as changing temperature and comfort of individuals,and indirect effects,such as greater frequency of storms, floods, infectious disease, food poisoning, and insect-induced and plant-induced allergies (9). Heat stress can be associated with psychological and physical effects such as irritability, nervousness, moodiness, depression (mental effects), cardiovascular complications, perspiration, water and electrolyte imbalance, and changes in blood flow rate (physical effects). A combination of mental and physical reactions is embodied in the form of low work efficiency, reduced labor skills, muscular fatigue, poor concentration, and thus, increased frequency of mistakes.

Environmental heat may lead to increased thermal load inside and outside the workplace, thereby decreasing the productivity of millions of workers (6). In general, productivity refers to the extent of efficiency in achieving the objectives of the system and is generally defined as the ratio of input to output (5). Workers in the construction industry, farmers, and fishermen may suffer from the thermal effects of climate change on productivity (10). To compensate for the loss of productivity due to heat stress, workers may be required to work longer hours or employers may be obliged to hire extra labor forces (6). In middle and low income countries, given the undesirable workplace conditions for both outdoor and indoor environments, productivity is often low (6). Currently, there is a paucity of research about the effects of heat stress on the performance and productivity of humans.Moreover, the existing data on the real exposure of workers to high-temperature environments and reduced productivity and efficiency are rather ambiguous (10). If the necessary control measures are not taken, high workplace temperature may have considerable effects on productivity, occupational efficiency, and their related costs. The aim of this study was to evaluate thermal stress and performance loss caused by high-temperature indoor work environments in Gonabad, Iran.

It should be noted that this study is the first of its type in Iran.Thus, its results can be incorporated in future studies to help prepare systematic plans for the protection of workers against this problem.

Material and Methods

This descriptive-analytical study was conducted on indoor high-temperature workplaces in the city of Gonabad. Consistent with the available literature, the stratified sampling method was used in the present in which each business unit or profession was considered as a stratum. Then, in proportion to the size of each stratum, a number of units were selected randomly. In this study, 15 bakeries, including 3 Barbari, 4 Sangak, and 8 Lavash bread baking bakeries, 11restaurants and kitchens, and 2 high-temperature industries including refractory brick manufacturing and porcelain industries all of which are enclosed or indoor high-temperature jobs, were examined. In total, 1450 individuals worked on the investigated sites and were exposed to thermal stress. Since in this study measurement of heat stress was conductedthrough public and environmental method, personnel demographic characteristics, such as age and sex,were not considered as intervening factors. The inclusion criterion for this study was workingin an environment that included a heating process and the exclusion criterion was unwillingness to participate in the study.All individuals and managers were informed of the aims of the project and were assured of the confidentialityof data. The WBGT index was used to measure heat stress.

WBGT-meter device (Model MK427JY,Casella Company in Australia) was used to measure environmental parameters such as dry temperature, wet temperature, and radiant temperature in the 3 positions of the workers’ head (1.7 m), body (1.1 m), and ankle (0.1m), respectively.Measurements were performed at 3 heights because the level of heat stress varied at different heights, on average, more than 3 °C, especially in bakeries.

Considering that in indoor work environments, usually heat exchange takes place entirely during 45minutes, in all measurements, the thermometers were placed in the desired site for 45 minutes and the final temperature was recorded. Using the NIOSH equation (Equation 2), the mean value of this index was determined at workplaces for each worker. The values of WBGT heat stress index and standard threshold limit value (TLV) of heat stress were compared with respect to the type of work, working time, and rest periods.

.jpg)

WhereTnw is the natural wet-bulb temperature and Tg is the globe thermometer temperature, and temperatures may be in either Celsius or Fahrenheit.

Finally, thermal stress was compared with the standard level (Table 1).

Table1: Occupational permissible exposure limit for heat stress exposure based on wet-bulb globe temperature (WBGT) index (

| Level of care (action) | PEL | Level of care (action) | PEL | Action limit | PEL | Action limit | PEL | Percentage (%) |

| 28 | 31 | 25 | 28 | - | - | - | - | 75-100 |

| 28.5 | 31 | 26 | 29 | 24 | 27.5 | - | - | 50-75 |

| 29.5 | 32 | 27 | 30 | 25.5 | 29 | 24.5 | 28 | 25-50 |

| 30 | 32.5 | 29 | 31.5 | 28 | 30.5 | 27 | 30 | 0-25 |

PEL: Permissible exposure limit

In the table 1,the percentage column represents the percentage of working time that the individual is exposed to thermal stress.

To estimate the decline in production (performance loss) caused by heat stress, we drew on the findings of Kjellstrom et al. in connection with the relationship between human work capacity and increased WBGT. Kjellstrom et al., based on ISO standard and NIOSH, designed a graph to demonstrate work efficiency decline in terms of increased WBGT value(6). Using ISO standard and NIOSH, they drew a graph of work capacity for non-adapted individuals as a function of WBGT index, which represented work capacity in 4 different intensity levels (2).The relationship between work capacity and WBGT with respect to 4 intensities was first proposed by Kjellstrom et al. in 2009 (2) in accordance with international standards (8) recommended by NIOSH, USA (10) (Figure1).

To estimate the decline in production (performance loss) caused by heat stress, we drew on the findings of Kjellstrom et al. in connection with the relationship between human work capacity and increased WBGT. Kjellstrom et al., based on ISO standard and NIOSH, designed a graph to demonstrate work efficiency decline in terms of increased WBGT value(6). Using ISO standard and NIOSH, they drew a graph of work capacity for non-adapted individuals as a function of WBGT index, which represented work capacity in 4 different intensity levels (2).The relationship between work capacity and WBGT with respect to 4 intensities was first proposed by Kjellstrom et al. in 2009 (2) in accordance with international standards (8) recommended by NIOSH, USA (10) (Figure1).

.jpg)

Figure1: The relationship between work capacity and wet-bulb globe temperature(WBGT) with respect to four intensities

In the above graph, the vertical axis represents the percentage of maximum physical capacity. All the studied working groups in this research were working using their arms and torso and carrying heavy objects.Thus, according to the standard job categorization of ISO 7243 in terms of the average energy metabolism, the metabolism production was estimated at about 414 watt, which is categorized as a heavy job (4). For data analysis, descriptive statistics were used in SPSS software (version 16; SPSS Inc., Chicago, IL, USA). In addition, Kolmogorov-Smirnov test was adopted to test the normality of data and the one sample t-test was used to compare the results with the standards.

Results

The results of thermal stress measurement and performance loss in different types of bakeries are shown in table 2 and figure 2.

Results

The results of thermal stress measurement and performance loss in different types of bakeries are shown in table 2 and figure 2.

.jpg)

Figure2. Thermal stress and its consequent performance loss in bakeries

According to the results of table 1, mean WBGT index in Barbari, Sangak and Lavash bakeries were 29.73, 27.89, and 29.43 °C, respectively. The results of thermal stress measurement at the ankle, abdomen, and head showed that, in all 3 types of bakeries under study, the maximum exposure to thermal stress was in the head area. The thermal stress in Sangak bakery was found to be lower than Barabri and Lavash bakeries.

Table 2: Results of heat stress evaluation in bakeries around the city of Gonabad, Iran, in spring 2014 (℃)

| Non-adapted individuals | Performance loss (%) | WBGTWhole body | WBGT Head | WBGT Waist | WBGTFoot | Dispersion index | Sampling site | |

| Test statistics | Significance level | |||||||

| 11.41 | < 0.001 | 65 | 29.73 ± 80 | 31.74 ± 1.70 | 29.73 ± 0.81 | 27.73 ± 0.97 | Mean± SD | Barbari bakery |

| 42 | 28.62 | 29.8 | 27.90 | 26.6 | Minimum | |||

| 73 | 30.67 | 34.1 | 30.90 | 28.9 | Maximum | |||

| 1.92 | 0.96 | 23 | 27.89 ± 2.78 | 27.78 ± 3.4 | 27.58 ± 2.66 | 26.8 ± 4.08 | Mean ±SD | Sangak bakery |

| 0 | 23.75 | 24.3 | 23.30 | 22 | Minimum | |||

| 88 | 31.18 | 32.9 | 30.90 | 34.9 | Maximum | |||

| 4.94 | < 0.001 | 64 | 29.43 ± 2.77 | 32.27 ± 3.18 | 29.50 ± 3.40 | 26.45 ± 2.31 | Mean | Lavash bakery |

| 0 | 25.07 | 29.60 | 22.60 | 22.4 | Minimum | |||

| 98 | 33.55 | 38.50 | 35.50 | 31 | Maximum | |||

WBGT: Wet-bulb globe temperature

Table3:Results of thermal stress in kitchens, and refractory brick and porcelain manufacturing industries

Table3:Results of thermal stress in kitchens, and refractory brick and porcelain manufacturing industries

| Performance loss (%) | WBGT whole body | WBGT head | WBGT waist | WBGT foot | Central or dispersion index | Sampling site |

| 89 | 32.04 ± 0.62 | 31.53 ± 1.09 | 32.23 ± 0.30 | 32.16 ± 1.04 | Mean ± SD | Refractory brick manufacturing industry |

| 33 | 30.67 | 30.5 | 30.5 | 31.2 | Minimum | |

| 90 | 32.92 | 32.4 | 33.1 | 33.1 | Maximum | |

| 92 | 32.35 ± 3.79 | 36.56 ± 4.83 | 32.66 ± 4.27 | 27.53 ± 1.80 | Mean ± SD | Porcelain manufacturing industry |

| 58 | 28.63 | 31 | 29 | 25.52 | Minimum | |

| 100 | 35.69 | 39.7 | 37.1 | 28.88 | Maximum | |

| 80 | 31.88 ± 3.12 | 33.96 ± 3.55 | 31.90 ± 3.03 | 29.76 ± 2.89 | Mean ± SD | Kitchens |

| 0 | 25.30 | 26.3 | 25.30 | 24.30 | Minimum | |

| 100 | 37.47 | 40.1 | 37.70 | 34.40 | Maximum |

According to the results of table 2 and figure 2, performance loss caused by heat stress,whichwas estimated using figure1, was 65%, 23%, and 64% in Barbari, Sangak, and Lavash bakeries, respectively. The highest performance loss was observed in Lavash bakery in which human performance could reduce up to 98%. The results of thermal stress measurement and its consequent performance loss in kitchens, and refractory brick and porcelain manufacturing industries are shown in table 3.

According to the results of table 2, the mean exposure to heat stress in porcelain and refractory brick manufacturing industries was 32.04 and 32.35 °C, which may lead to the loss of human performance as much as 89% and 92% , respectively.

According to the results of table 2, the mean exposure to heat stress in porcelain and refractory brick manufacturing industries was 32.04 and 32.35 °C, which may lead to the loss of human performance as much as 89% and 92% , respectively.

Figure 3: Results of test statistics measurement and level of significance with respect to wet-bulb globe temperature (WBGT) in the studied professions

The mean WBGT value in kitchens was 31.88, which can cause a performance loss of up to 80% in humans. The results of the present study indicated high variation in WBGT in kitchens, with a related performance loss of 0 to 100 in humans. The results of test statistics measurement and level of significance with regard to WBGT are shown in the figure 3. In the following figure, the vertical axis represents test statistics and significant levels.

Discussion

In the present study, mean exposure to heat stress in Barbari, Sangak, and Lavash bakeries was compared with the standard values (11) (Table 1).The results showed that, with the assumption that all tasks in bakeries are classified as heavy work with a 50% to 75% working capacity, all bakeries are exposed to excessive thermal stress (27.5 ºC) and its related health effects. The study byHannani on 175 workers in 100 bakeries revealed that 61% of them were subject to thermal stress (8). Their findings are consistent with the results of the present study.

In another study by Mohammad Ali Qajar Kohestani in 2004, the heat stress index was investigated in 70 randomly selected bakeries in the city of Sari, Iran (12). Their results suggested that WBGT values significantly differed in various bakeries, which were consistent with the results of the present study (12). In addition to the health effects, bakery workers experience performance loss due to heat stress. According to the results of table 1 and figure 2, 65%, 23%, and 64% performance loss was observed in Barbari, Sangak, and Lavash bakeries, respectively, which in some cases, can reduce human performance by around 98%.

The workers in the refractory brick manufacturing industry are also exposed to excessive heat stress and its consequent performance loss because the measured WBGT value in this industry (32.04°C) can result in a performance loss of 82% in humans. The work schedule of workers in the furnace unit of this industry is comprised of 75% working hours and 25% rest hours, and their job is classified as heavy in terms of energy consumption.

In general, in the two industries examined in this study, WBGT values were higher than the permissible exposure limit (PEL), with their workers experiencing performance loss as well as other complications associated with excessive thermal stress. According to the results presented in table 3, the mean WBGT value in kitchens was 31.88, which could lead to 80% loss of human performance. The results of this study showed high variation range of WBGT in kitchens with a subsequent performance loss of 0 to 10% in humans. Moreover, the results of this study suggested that workers engaged in indoor high-temperature professions such as bakeries, kitchens, and furnace units of various industries in the city of Gonabad were exposed to heat stress.

In addition to external heat, physical activities can also generate heat in the human body, with a subsequent increase in body temperature, which can affect the health and productivity of humans (5).

Reduced efficiency of physical and mental activities resulting from thermal stress has been proven (13). It is generally observed that with an abnormal increase in dehydration and a 10% decline in body water, body functions are increasingly reduced (14). The study by Kjellstrom et al. showed that in countries with warmer seasons, increase in the workers’ internal body temperature due to heat exposure was greater than the capacity of their physiological mechanism (15).

According to the results of the studyby Kjellstrom et al. in 2009, work capacity is reduced significantly with the increase of WBGT from 26 to 30 °C (15). The findings of another study suggest that in the absence of any specific compliance strategy, most countries in Southeast Asia, Central America, and the Caribbean will face a production decline of 10% to 27% (6).Based on the conceptual distribution graph of human productivity versus WBGT values based on ISO 7243 standard (16), in WBGT of higher than 25 °C, the human work capacity begins to drop.Moreover, in WBGT of over 40 °C, the performance of physical actions will be extremely difficult for all individuals (17).

Performance loss caused by heat stress can also decrease gross domestic product (GDP) from 0.1% to 0.5% (9). Studies have shown that at a temperature slightly above comfortable temperature (slightly higher than 20°C), the human performance begins to drop from 3% to 50%.Furthermore, in temperatures above comfort level (35 to 37 °C), this reduction can be as high as 75% (9). For example, office workers reach their maximum work capacity at a temperature of 23 °C, while their productivity is reduced up to 70% at a temperature of 30 °C (9). A study by the Ministry of Labor and Social Affairs of France showed that heat stress exposure among French workers was 16.6% (18).

In the present study, the results of thermal stress evaluation among workers of high-temperature industries of Gonabad indicated that furnace workers in the studied industries were exposed to thermal stress. Husseini, in his study on a tile manufacturing company based on WBGT index, concluded that thermal stress in the dryer department was greater than the PEL, though it was at normal level in other parts of the factory (4). This finding is consistent with the results of the present study. In addition, the results of another study by Srivastava on a glass industry in India showed that heat stress exposure of workers was greater than the recommended levels specified in the American Conference of Governmental Industrial Hygienists (ACGIH) standard (19). Additionally, the tight protective clothing used for pesticides may increase the risk of heat stress. Moreover, heavy physical work can also be a cause of thermal threat among construction workers as it can lead to an increase in work-related accidents. Accordingly, further serious problems should be prevented with the adoption of professional health control measures, including training and the application of personal protective equipment and air conditioning systems.The present study had some limitations.One limitation was that this study was conducted in the spring and due to seasonal temperature changes, the results of this study cannot be generalized to other seasons.Moreover,some business executives were not willing to cooperate with the project managers.

Conclusion

Most indoor high-temperature professions in the city of Gonabad entail exposure to thermal stress and its related complications and performance loss.Thus, it is necessary to take appropriate controlling and organizing measures to protect the workers subject to heat stress. As such, the following controlling measures are recommended:

1. Developing specific rules and guidelines for working in high-temperature workplaces and monitoring the implementation of such regulations

2. Organizing training programs about prevention and control of heat-related complications for workers and employers

3. Obligating all workers to pass heat adaptability courses before starting their work so as to prevent the effects of heat stress

4. Adopting engineering control measures as one of the most effective ways to manage heat stress

It should be notedthat it was not possible to separate adapted and non-adapted individuals in this study.Therefore, this study was carried out assuming that workers were not adapted to thermal conditions.Nevertheless, in the real situations, most workers are adapted to their workplace conditions, and thus, their performance loss will be less than the values reported in this study.

As a result, further studies are required to investigate performance loss among heat-adapted workers.

Acknowledgments

This study was approved as research project No. 44/92 at Gonabad University of Medical Sciences. The authors express their gratitude and appreciation to the Research Deputy of Gonabad University of Medical Sciences.

Conflict of interest: None declared.

Discussion

In the present study, mean exposure to heat stress in Barbari, Sangak, and Lavash bakeries was compared with the standard values (11) (Table 1).The results showed that, with the assumption that all tasks in bakeries are classified as heavy work with a 50% to 75% working capacity, all bakeries are exposed to excessive thermal stress (27.5 ºC) and its related health effects. The study byHannani on 175 workers in 100 bakeries revealed that 61% of them were subject to thermal stress (8). Their findings are consistent with the results of the present study.

In another study by Mohammad Ali Qajar Kohestani in 2004, the heat stress index was investigated in 70 randomly selected bakeries in the city of Sari, Iran (12). Their results suggested that WBGT values significantly differed in various bakeries, which were consistent with the results of the present study (12). In addition to the health effects, bakery workers experience performance loss due to heat stress. According to the results of table 1 and figure 2, 65%, 23%, and 64% performance loss was observed in Barbari, Sangak, and Lavash bakeries, respectively, which in some cases, can reduce human performance by around 98%.

The workers in the refractory brick manufacturing industry are also exposed to excessive heat stress and its consequent performance loss because the measured WBGT value in this industry (32.04°C) can result in a performance loss of 82% in humans. The work schedule of workers in the furnace unit of this industry is comprised of 75% working hours and 25% rest hours, and their job is classified as heavy in terms of energy consumption.

In general, in the two industries examined in this study, WBGT values were higher than the permissible exposure limit (PEL), with their workers experiencing performance loss as well as other complications associated with excessive thermal stress. According to the results presented in table 3, the mean WBGT value in kitchens was 31.88, which could lead to 80% loss of human performance. The results of this study showed high variation range of WBGT in kitchens with a subsequent performance loss of 0 to 10% in humans. Moreover, the results of this study suggested that workers engaged in indoor high-temperature professions such as bakeries, kitchens, and furnace units of various industries in the city of Gonabad were exposed to heat stress.

In addition to external heat, physical activities can also generate heat in the human body, with a subsequent increase in body temperature, which can affect the health and productivity of humans (5).

Reduced efficiency of physical and mental activities resulting from thermal stress has been proven (13). It is generally observed that with an abnormal increase in dehydration and a 10% decline in body water, body functions are increasingly reduced (14). The study by Kjellstrom et al. showed that in countries with warmer seasons, increase in the workers’ internal body temperature due to heat exposure was greater than the capacity of their physiological mechanism (15).

According to the results of the studyby Kjellstrom et al. in 2009, work capacity is reduced significantly with the increase of WBGT from 26 to 30 °C (15). The findings of another study suggest that in the absence of any specific compliance strategy, most countries in Southeast Asia, Central America, and the Caribbean will face a production decline of 10% to 27% (6).Based on the conceptual distribution graph of human productivity versus WBGT values based on ISO 7243 standard (16), in WBGT of higher than 25 °C, the human work capacity begins to drop.Moreover, in WBGT of over 40 °C, the performance of physical actions will be extremely difficult for all individuals (17).

Performance loss caused by heat stress can also decrease gross domestic product (GDP) from 0.1% to 0.5% (9). Studies have shown that at a temperature slightly above comfortable temperature (slightly higher than 20°C), the human performance begins to drop from 3% to 50%.Furthermore, in temperatures above comfort level (35 to 37 °C), this reduction can be as high as 75% (9). For example, office workers reach their maximum work capacity at a temperature of 23 °C, while their productivity is reduced up to 70% at a temperature of 30 °C (9). A study by the Ministry of Labor and Social Affairs of France showed that heat stress exposure among French workers was 16.6% (18).

In the present study, the results of thermal stress evaluation among workers of high-temperature industries of Gonabad indicated that furnace workers in the studied industries were exposed to thermal stress. Husseini, in his study on a tile manufacturing company based on WBGT index, concluded that thermal stress in the dryer department was greater than the PEL, though it was at normal level in other parts of the factory (4). This finding is consistent with the results of the present study. In addition, the results of another study by Srivastava on a glass industry in India showed that heat stress exposure of workers was greater than the recommended levels specified in the American Conference of Governmental Industrial Hygienists (ACGIH) standard (19). Additionally, the tight protective clothing used for pesticides may increase the risk of heat stress. Moreover, heavy physical work can also be a cause of thermal threat among construction workers as it can lead to an increase in work-related accidents. Accordingly, further serious problems should be prevented with the adoption of professional health control measures, including training and the application of personal protective equipment and air conditioning systems.The present study had some limitations.One limitation was that this study was conducted in the spring and due to seasonal temperature changes, the results of this study cannot be generalized to other seasons.Moreover,some business executives were not willing to cooperate with the project managers.

Conclusion

Most indoor high-temperature professions in the city of Gonabad entail exposure to thermal stress and its related complications and performance loss.Thus, it is necessary to take appropriate controlling and organizing measures to protect the workers subject to heat stress. As such, the following controlling measures are recommended:

1. Developing specific rules and guidelines for working in high-temperature workplaces and monitoring the implementation of such regulations

2. Organizing training programs about prevention and control of heat-related complications for workers and employers

3. Obligating all workers to pass heat adaptability courses before starting their work so as to prevent the effects of heat stress

4. Adopting engineering control measures as one of the most effective ways to manage heat stress

It should be notedthat it was not possible to separate adapted and non-adapted individuals in this study.Therefore, this study was carried out assuming that workers were not adapted to thermal conditions.Nevertheless, in the real situations, most workers are adapted to their workplace conditions, and thus, their performance loss will be less than the values reported in this study.

As a result, further studies are required to investigate performance loss among heat-adapted workers.

Acknowledgments

This study was approved as research project No. 44/92 at Gonabad University of Medical Sciences. The authors express their gratitude and appreciation to the Research Deputy of Gonabad University of Medical Sciences.

Conflict of interest: None declared.

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution 4.0 International License. |