Volume 13, Issue 2 (Spring 2024)

J Occup Health Epidemiol 2024, 13(2): 76-98 |

Back to browse issues page

Ethics code: IR.MODARES.REC.1400.295

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Naghshbandi A, Ahmadi O, Asilian Mahabad H. Analyzing the Causes and Safety Barriers of Accidents in Gas Pipeline Excavation and Piping Operations Using Tripod Beta and Bowtie Methods: A Case Study of "Struck By" Accidents. J Occup Health Epidemiol 2024; 13 (2) :76-98

URL: http://johe.rums.ac.ir/article-1-717-en.html

URL: http://johe.rums.ac.ir/article-1-717-en.html

Related article in

Google Scholar

Google Scholar

Similar articles

1- M.Sc. Student in Occupational Health and Safety Engineering, Occupational Health and Safety Engineering, Faculty of Medical Sciences, Tharbiat Modares University, Tehran, Iran.

2- Assistant Prof., Occupational Health and Safety Engineering, Faculty of Medical Sciences, Tarbiat Modares University, Tehran, Iran. ,o.ahmadi@modares.ac.ir

3- Professor, Occupational Health and Safety Engineering, Faculty of Medical Sciences, Tarbiat Modares University, Tehran, Iran.

2- Assistant Prof., Occupational Health and Safety Engineering, Faculty of Medical Sciences, Tarbiat Modares University, Tehran, Iran. ,

3- Professor, Occupational Health and Safety Engineering, Faculty of Medical Sciences, Tarbiat Modares University, Tehran, Iran.

Article history

Received: 2023/03/4

Accepted: 2024/04/23

ePublished: 2024/06/26

Accepted: 2024/04/23

ePublished: 2024/06/26

Subject:

Occupational Health

Full-Text [PDF 1716 kb]

(652 Downloads)

| Abstract (HTML) (1380 Views)

Fig. 1. The connection between Tripod beta and Bowtie method [24].

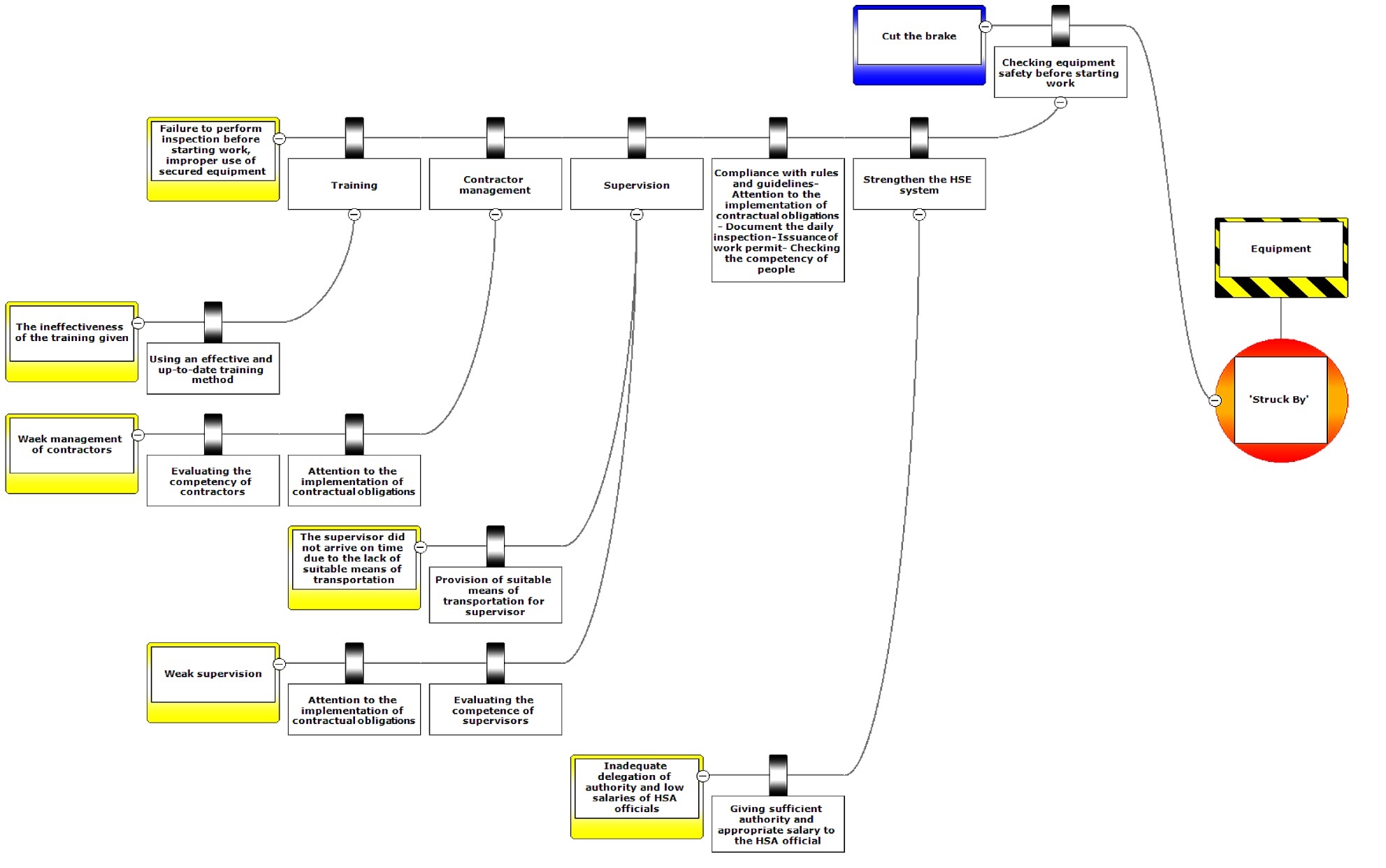

Fig. 2. Tripod Beta diagram for ˈStruck By

Table 3. Classification of basic risk factors based on the Tripod Beta method

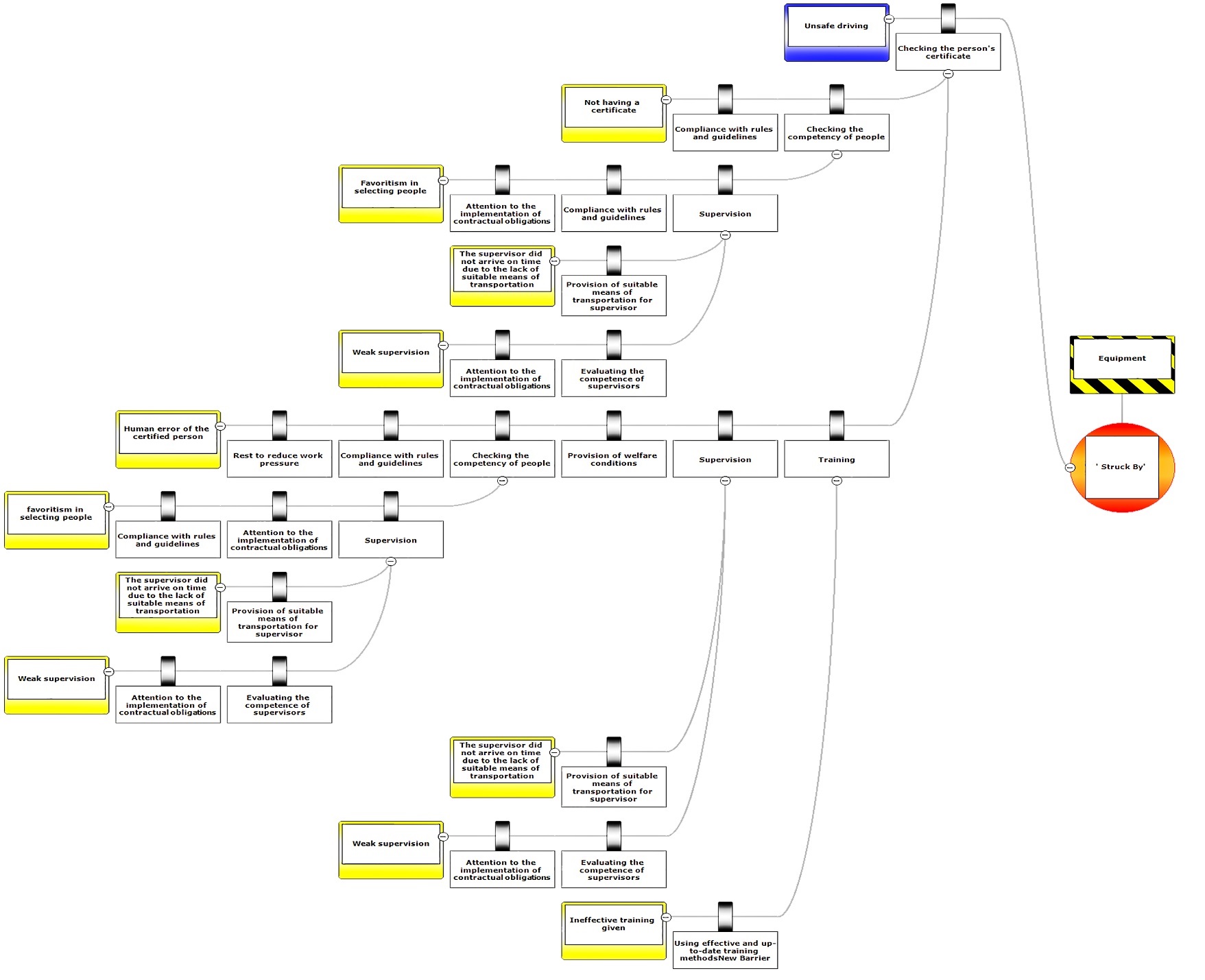

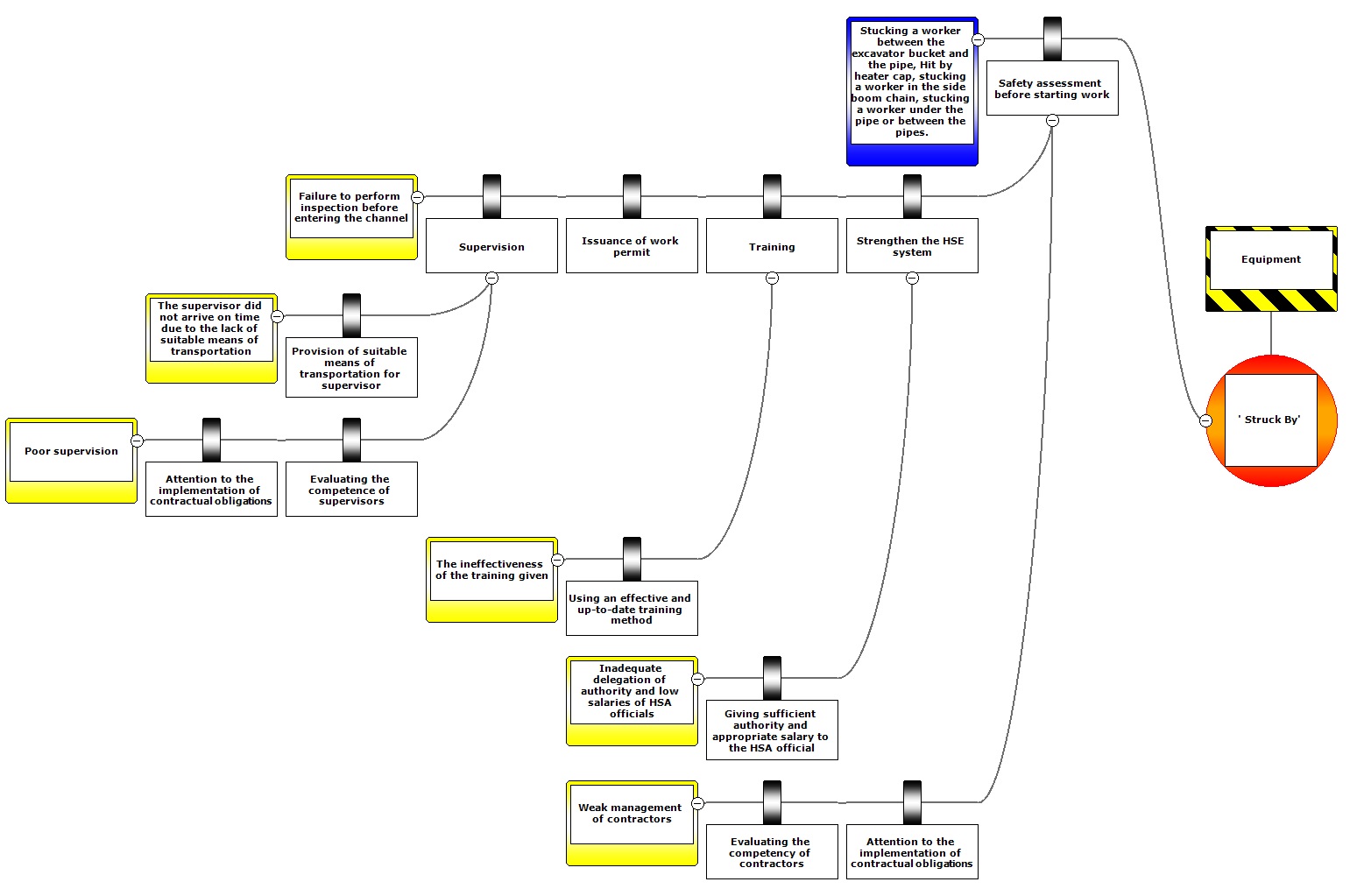

Fig. 4. Bowtie diagram for "Struck By"

Table 4. Escalation factors of safety barriers in Bowtie diagram.

Table 5. Escalation factors in the Bowtie diagram

Full-Text: (681 Views)

Introduction

One of the most important problems in the industry is the occurrence of accidents and occupational diseases [1]. According to the statistics of the International Labor Organization (ILO.2021), more than 2.78 million workers worldwide die from occupational accidents every year, and 374 million more experience non-fatal occupational accidents, with the construction industry accounting for roughly 60% of these fatalities [2]. According to the studies conducted, there were few studies to identify the factors that influence the occurrence of accidents [3]. About 33% of work-related

deaths are due to occupational accidents [4]. As the third leading cause of death in the world and second only to road accidents in Iran, occupational injuries are one of the important and fundamental factors in the safety, health, and economic debate in developing countries [5]. According to the collected statistics, there are about 14,000 occupational accidents occur in Iran every year, most of them in industry [6]. Most of the injuries and deaths in the oil industry are caused by occupational accidents [7].

The Pipeline and Hazardous Materials Safety Administration (PHMSA) in the United States keeps track of the frequency of pipeline failures, incidents, and accidents. PHMSA data shows that in the last 20 years through 2021, there will be an average of 640 pipeline accidents, 14 deaths, and 57 injuries yearly. 31.41% of the causes of these accidents were related to equipment failure [8]. In Iran, there are no official and new statistics of the exact number of accidents related to gas pipelines or "Struck By" and the number of deaths and injuries.

According to the "Workplace Hazard Classes Notification for Occupational Health and Safety", the construction sector falls into the very dangerous sector class category. The number of deaths and injuries in the statistics of work accidents supports this statement. As stated in the 2021 SSI Statistics annuals, in the construction sector, 58107 employees were exposed to work accidents, and 386 employees lost their lives due to work accidents. According to the list of workplace hazard classes included in the notification annex, excavation and excavation works (preparation of agricultural land, blasting and removal of rocks, drainage of construction sites, filling, etc.) are included in those mentioned above very dangerous class [9].

Among the models for investigation and analysis of accidents caused by work, we can mention Henrich's domino model, Embry machine model, SEM-Tomas model, STAMP model, Tripod Beta model, Bowtie model, etc. In this study, Bowtie and Tripod Beta methods are used to identify the causes because, in addition to identifying threats and obstacles, they categorize the basic risk factors and help to rank and take corrective measures. Using the Tripod Beta method, the Bowtie method can help identify obstacles related to an incident. The reason for using the discussed method is that, according to the studies, human and organizational factors directly and indirectly play a fundamental role in accidents. These methods are used to review the defects and failures that occurred in an incident, and this goal can be reached by reviewing the recorded incident report.

The Tripod Beta analysis method is derived from the Tripod method, which is based on the Swiss cheese model. This model, developed by Reason in 1990, suggests that an accident occurs due to a combination of errors and negligence at various levels of the organization. The name Tripod was derived from the three legs: incidents/accidents, basic risk factors (BRFs), and unsafe acts. In the Tripod method, an accident occurs due to missing or failing controls and barriers. Unsafe acts (active failures) are caused by underlying mechanisms acting in organizations. These mechanisms, called BRF, cover human, organizational, and technical problems. The Tripod Beta model directly links barriers and controls to unsafe acts, preconditions, and latent failures. In the Tripod model, barriers and controls are directly linked to the BRF. Based on this model, BRF leads to preconditions and, subsequently, active failures [10].

Shafiei et al. analyzed the causes and responsibilities of occupational accidents in an automotive company. For this purpose, 20 important accidents of an automotive company were selected, and the root causes, the parties involved in the accidents, and the respective responsibility rates were determined by 10 experts based on dividing into 11 Tripod Beta basic risk factors and using occupational accident tree analysis and occupational accident component analysis techniques. The results revealed that among the defects in the management system, the organizational system’s defects had the greatest impact on the occurrence of occupational accidents. By modifying about half of the basic risk factors, 80% of occupational accidents can be controlled. Also, by focusing on monitoring and design units, the company’s accidents can be reduced by up to 50% [11].

Bowtie analysis can be considered a hybrid technique as an enhanced combination of fault tree and event tree analysis. The bowtie technique delivers a prompt view of the preventive barriers of the system and its layers of protection. The Bowtie methodology is an approach to study major accident events and analyze the components that might lead to undesired consequences [12].

In a paper, a risk identification based on the Bowtie analysis is formulated, exploring a subsea pipeline system. Transporting dangerous materials by subsea pipelines during field operation is defined as a hazardous situation. The major pipeline causes during the field operation are also considered: external and internal corrosion; material, weld, and equipment failures; incorrect operation; and external interference. Based on this information, it is established that the main failure modes of subsea pipelines during the transport of dangerous materials by subsea pipelines are mechanical, structural, and external interference failures. Furthermore, environmental and financial aspects are considered in analysing the main consequences in the Bowtie diagram. Finally, barriers are implemented to prevent an undesirable incident or limit the consequences. The Bowtie helps structure the problem and consequently monitor the effectiveness of preventive and mitigating barriers, allowing risks to be better understood and managed over time, recording causes and consequences, and preventive and reactive controls for better monitoring [13]. Among the limitations of common risk assessment methods, such as the fault tree, event tree, and Bowtie method, is that new information and evidence cannot be included in these methods, or the so-called model can be updated. Also, in these methods, the relationship between variables is not accurately identified. Among other limitations of these methods, it can be mentioned that these methods cannot manage the lack of data and the uncertainty of data, and they do not have the necessary ability to update and infer [14,15].

Shannon et al., in their study, examined the relationship between organizational factors and the work environment and their impact on occupational accidents. The study concluded that employee authority, willingness and delegation of safety activities, and the active and proactive role of health and safety managers, were significantly associated with lower rates of accidents and injuries as well as mortality [16].

Quantitative risk assessment is a systematic method for identifying and prioritizing various variables in the evolution of an accident. Quantitative risk assessment can provide a basis for increasing risk awareness. Based on the quantitative results of the risk assessment, potential measures to control or mitigate the risk can be implemented and evaluated [17]. To address risks in an ever-evolving environment and overcome the limitations of traditional methods, new risk assessment methodologies evolve dynamically, continuously incorporating accurate information and improving to better address current risks [18]. Therefore, the need for new tools and methods is felt in developing safety management and using new methods in the analysis of accidents and leading indicators [19].

According to PHMSA data, one of the causes of pipeline accidents in the US is outside forces such as "Struck By" [20].

Excavated tunnels are a leading cause of death in excavation operations. These workers are also at risk when working at heights, with heavy equipment, handling materials, or near existing utility sources such as power and gas pipelines.

Due to the lack of studies in the field of identifying the causes and obstacles of "Struck By" accidents in excavation and piping operations, this study was conducted.

This study aims to analyze "Struck By" incidents during excavation and piping operations of gas pipelines safety barriers with the Bowtie and Tripod Beta methods.

Materials and Methods

Analyzed accidents data: To identify the causes of accidents, this study first collects "Struck By" accidents in gas pipeline excavation and piping operations over the past decade (2013-2023). According to OSHA, “Struck” is injuries produced by forcible contact or impact between the injured person and an object or piece of equipment. "Struck By" accidents are categorized as "Struck By" flying objects, falling objects, swinging objects, and rolling objects [21]. These accidents are then analyzed by the Tripod beta and Bowtie method to identify causes and safety barriers.

Analysis of events: First, we used Tripod Beta to analyze the causes of "Struck By" incidents during gas pipeline excavation and piping operations over the past decade (2013-2023). Tripod Beta is an approach to accident analysis using accident cause theory and hazard and effects management processes [22]. The Tripod Beta analysis examines the causes of a series of accidents. Analysis shows how the accident occurred, which barriers failed, and why those barriers failed. Tripod Beta is based on building a tree structure representing accident mechanisms, events, and their relationships [23]. Based on the studies, the Tripod Beta method categorizes underlying causes into 11 Basic Risk Factors (BRFs) (table 1). The symbols used in the tripod tree include the following:

⁕An event node represents damage, injury, or loss.

⁕An agent node is the presence of a necessary potential to change, harm, or damage a target.

⁕An object node indicates the presence of an entity (e.g., person, equipment, credit, project schedule) vulnerable to the agent.

⁕A failed barrier node allows the agent and object to encounter and cause an event.

⁕The immediate cause is the human action or technical failure that caused the failure of the barrier and is directly connected to it.

⁕A precondition node increases the probability of the immediate cause of a failed barrier.

⁕Underlying causes are the source of organizational preconditions. By this definition, underlying causes would be the "final" node.

⁕An effective barrier node represents a barrier that has not failed and successfully restrains the agent or protects the object.

⁕Missing/inadequate barrier refers to a barrier that the operational plans and procedures have determined exists but the incident investigation shows that none have been created, or that it is not present at the site, or, if present, to play a role in are considered insufficient [24].

One of the most important problems in the industry is the occurrence of accidents and occupational diseases [1]. According to the statistics of the International Labor Organization (ILO.2021), more than 2.78 million workers worldwide die from occupational accidents every year, and 374 million more experience non-fatal occupational accidents, with the construction industry accounting for roughly 60% of these fatalities [2]. According to the studies conducted, there were few studies to identify the factors that influence the occurrence of accidents [3]. About 33% of work-related

deaths are due to occupational accidents [4]. As the third leading cause of death in the world and second only to road accidents in Iran, occupational injuries are one of the important and fundamental factors in the safety, health, and economic debate in developing countries [5]. According to the collected statistics, there are about 14,000 occupational accidents occur in Iran every year, most of them in industry [6]. Most of the injuries and deaths in the oil industry are caused by occupational accidents [7].

The Pipeline and Hazardous Materials Safety Administration (PHMSA) in the United States keeps track of the frequency of pipeline failures, incidents, and accidents. PHMSA data shows that in the last 20 years through 2021, there will be an average of 640 pipeline accidents, 14 deaths, and 57 injuries yearly. 31.41% of the causes of these accidents were related to equipment failure [8]. In Iran, there are no official and new statistics of the exact number of accidents related to gas pipelines or "Struck By" and the number of deaths and injuries.

According to the "Workplace Hazard Classes Notification for Occupational Health and Safety", the construction sector falls into the very dangerous sector class category. The number of deaths and injuries in the statistics of work accidents supports this statement. As stated in the 2021 SSI Statistics annuals, in the construction sector, 58107 employees were exposed to work accidents, and 386 employees lost their lives due to work accidents. According to the list of workplace hazard classes included in the notification annex, excavation and excavation works (preparation of agricultural land, blasting and removal of rocks, drainage of construction sites, filling, etc.) are included in those mentioned above very dangerous class [9].

Among the models for investigation and analysis of accidents caused by work, we can mention Henrich's domino model, Embry machine model, SEM-Tomas model, STAMP model, Tripod Beta model, Bowtie model, etc. In this study, Bowtie and Tripod Beta methods are used to identify the causes because, in addition to identifying threats and obstacles, they categorize the basic risk factors and help to rank and take corrective measures. Using the Tripod Beta method, the Bowtie method can help identify obstacles related to an incident. The reason for using the discussed method is that, according to the studies, human and organizational factors directly and indirectly play a fundamental role in accidents. These methods are used to review the defects and failures that occurred in an incident, and this goal can be reached by reviewing the recorded incident report.

The Tripod Beta analysis method is derived from the Tripod method, which is based on the Swiss cheese model. This model, developed by Reason in 1990, suggests that an accident occurs due to a combination of errors and negligence at various levels of the organization. The name Tripod was derived from the three legs: incidents/accidents, basic risk factors (BRFs), and unsafe acts. In the Tripod method, an accident occurs due to missing or failing controls and barriers. Unsafe acts (active failures) are caused by underlying mechanisms acting in organizations. These mechanisms, called BRF, cover human, organizational, and technical problems. The Tripod Beta model directly links barriers and controls to unsafe acts, preconditions, and latent failures. In the Tripod model, barriers and controls are directly linked to the BRF. Based on this model, BRF leads to preconditions and, subsequently, active failures [10].

Shafiei et al. analyzed the causes and responsibilities of occupational accidents in an automotive company. For this purpose, 20 important accidents of an automotive company were selected, and the root causes, the parties involved in the accidents, and the respective responsibility rates were determined by 10 experts based on dividing into 11 Tripod Beta basic risk factors and using occupational accident tree analysis and occupational accident component analysis techniques. The results revealed that among the defects in the management system, the organizational system’s defects had the greatest impact on the occurrence of occupational accidents. By modifying about half of the basic risk factors, 80% of occupational accidents can be controlled. Also, by focusing on monitoring and design units, the company’s accidents can be reduced by up to 50% [11].

Bowtie analysis can be considered a hybrid technique as an enhanced combination of fault tree and event tree analysis. The bowtie technique delivers a prompt view of the preventive barriers of the system and its layers of protection. The Bowtie methodology is an approach to study major accident events and analyze the components that might lead to undesired consequences [12].

In a paper, a risk identification based on the Bowtie analysis is formulated, exploring a subsea pipeline system. Transporting dangerous materials by subsea pipelines during field operation is defined as a hazardous situation. The major pipeline causes during the field operation are also considered: external and internal corrosion; material, weld, and equipment failures; incorrect operation; and external interference. Based on this information, it is established that the main failure modes of subsea pipelines during the transport of dangerous materials by subsea pipelines are mechanical, structural, and external interference failures. Furthermore, environmental and financial aspects are considered in analysing the main consequences in the Bowtie diagram. Finally, barriers are implemented to prevent an undesirable incident or limit the consequences. The Bowtie helps structure the problem and consequently monitor the effectiveness of preventive and mitigating barriers, allowing risks to be better understood and managed over time, recording causes and consequences, and preventive and reactive controls for better monitoring [13]. Among the limitations of common risk assessment methods, such as the fault tree, event tree, and Bowtie method, is that new information and evidence cannot be included in these methods, or the so-called model can be updated. Also, in these methods, the relationship between variables is not accurately identified. Among other limitations of these methods, it can be mentioned that these methods cannot manage the lack of data and the uncertainty of data, and they do not have the necessary ability to update and infer [14,15].

Shannon et al., in their study, examined the relationship between organizational factors and the work environment and their impact on occupational accidents. The study concluded that employee authority, willingness and delegation of safety activities, and the active and proactive role of health and safety managers, were significantly associated with lower rates of accidents and injuries as well as mortality [16].

Quantitative risk assessment is a systematic method for identifying and prioritizing various variables in the evolution of an accident. Quantitative risk assessment can provide a basis for increasing risk awareness. Based on the quantitative results of the risk assessment, potential measures to control or mitigate the risk can be implemented and evaluated [17]. To address risks in an ever-evolving environment and overcome the limitations of traditional methods, new risk assessment methodologies evolve dynamically, continuously incorporating accurate information and improving to better address current risks [18]. Therefore, the need for new tools and methods is felt in developing safety management and using new methods in the analysis of accidents and leading indicators [19].

According to PHMSA data, one of the causes of pipeline accidents in the US is outside forces such as "Struck By" [20].

Excavated tunnels are a leading cause of death in excavation operations. These workers are also at risk when working at heights, with heavy equipment, handling materials, or near existing utility sources such as power and gas pipelines.

Due to the lack of studies in the field of identifying the causes and obstacles of "Struck By" accidents in excavation and piping operations, this study was conducted.

This study aims to analyze "Struck By" incidents during excavation and piping operations of gas pipelines safety barriers with the Bowtie and Tripod Beta methods.

Materials and Methods

Analyzed accidents data: To identify the causes of accidents, this study first collects "Struck By" accidents in gas pipeline excavation and piping operations over the past decade (2013-2023). According to OSHA, “Struck” is injuries produced by forcible contact or impact between the injured person and an object or piece of equipment. "Struck By" accidents are categorized as "Struck By" flying objects, falling objects, swinging objects, and rolling objects [21]. These accidents are then analyzed by the Tripod beta and Bowtie method to identify causes and safety barriers.

Analysis of events: First, we used Tripod Beta to analyze the causes of "Struck By" incidents during gas pipeline excavation and piping operations over the past decade (2013-2023). Tripod Beta is an approach to accident analysis using accident cause theory and hazard and effects management processes [22]. The Tripod Beta analysis examines the causes of a series of accidents. Analysis shows how the accident occurred, which barriers failed, and why those barriers failed. Tripod Beta is based on building a tree structure representing accident mechanisms, events, and their relationships [23]. Based on the studies, the Tripod Beta method categorizes underlying causes into 11 Basic Risk Factors (BRFs) (table 1). The symbols used in the tripod tree include the following:

⁕An event node represents damage, injury, or loss.

⁕An agent node is the presence of a necessary potential to change, harm, or damage a target.

⁕An object node indicates the presence of an entity (e.g., person, equipment, credit, project schedule) vulnerable to the agent.

⁕A failed barrier node allows the agent and object to encounter and cause an event.

⁕The immediate cause is the human action or technical failure that caused the failure of the barrier and is directly connected to it.

⁕A precondition node increases the probability of the immediate cause of a failed barrier.

⁕Underlying causes are the source of organizational preconditions. By this definition, underlying causes would be the "final" node.

⁕An effective barrier node represents a barrier that has not failed and successfully restrains the agent or protects the object.

⁕Missing/inadequate barrier refers to a barrier that the operational plans and procedures have determined exists but the incident investigation shows that none have been created, or that it is not present at the site, or, if present, to play a role in are considered insufficient [24].

Table 1. Classification of the basic risk factors in the Tripod Beta method [24]

| No. | BRFs | Abbreviation | Definition |

| 1 | Design | DE | Poor design of tools or equipment |

| 2 | Tools and Equipment | TE | Poor quality, condition, suitability, or availability of materials, tools, equipment, and components |

| 3 | Maintenance Management | MM | No or inadequate performance of maintenance tasks and repairs |

| 4 | Housekeeping | HK | No or insufficient attention paid to keeping the work floor clean or tidied up |

| 5 | Error enforcing conditions | EC | Unsuitable physical performance of maintenance tasks and repairs |

| 6 | Procedures | PR | Insufficient quality or availability of procedures, guidelines, instructions, and manuals |

| 7 | Training | TR | No or insufficient competence or experience among employees |

| 8 | Communications | CO | No or ineffective communication between the various sites, departments, or employees of a company or with the officials' bodies |

| 9 | Incompatible goals | IG | The situation in which employees must choose between optimal working methods according to the established rules on the one hand and the pursuit of production, financial, political, social, or individual goals on the other |

| 10 | Organization | OR | Shortcomings in the organization’s structure, organization’s philosophy, organizational processes, or management strategies, resulting in inadequate or ineffective management of the company |

| 11 | Defenses | DF | No or insufficient protection of people, materials, and environment against the consequences of the operational disturbances |

Safety barriers and escalation factors: The Tripod Beta method was used to identify the causes of these accidents, and the Bowtie method was used to identify safety barriers and risk influence factors (RIF) for these accident scenarios. A Bowtie is a graphical way of showing an accident scenario from cause to effect. This method is a hybrid of the fault tree and event tree methods, and it provides an understanding of the causes, consequences, safety barriers that could have prevented the accident, and the escalation factors that affect the performance of safety barriers. According to the Bowtie diagram, the incident is investigated in two stages: "before the incident" and "after the incident". In the first stage (left side of the diagram), words such as risk, obstacle and escalation factor are examined. The logic of this part of the diagram is based on the fact that any activity or operation has a potential risk and potential for harm, and if these risks are left, threats will be created. Therefore, to prevent threats, suitable obstacles should be predicted and placed in the path of these risks to prevent the unwanted release of risks. To ensure the effectiveness of the anticipated barriers, the escalation factors that may have an adverse effect on them should be identified, and the escalation factor controls should be considered. HSE critical functions support all escalation factor controls to ensure their correct and effective operation [24].

Fig. 1. The connection between Tripod beta and Bowtie method [24].

Results

Collecting data: Data related to 8 "Struck By" accidents were collected. All these accidents caused casualties. In each incident, one person died, and the equipment was damaged. The activities that led to the accident included Leak resistance test operation, Pipeline troubleshooting, Daily visit operation of the CGS station, Insulation and sandblasting operations, Pipe welding operation, Channel digging operation to install a valve device. This process provides assembly conditions for performing welding operations and the final connection of two pipelines and Pipe separation operation. Table 2 provides an overview of the "Struck By" analyzed in this study.

Collecting data: Data related to 8 "Struck By" accidents were collected. All these accidents caused casualties. In each incident, one person died, and the equipment was damaged. The activities that led to the accident included Leak resistance test operation, Pipeline troubleshooting, Daily visit operation of the CGS station, Insulation and sandblasting operations, Pipe welding operation, Channel digging operation to install a valve device. This process provides assembly conditions for performing welding operations and the final connection of two pipelines and Pipe separation operation. Table 2 provides an overview of the "Struck By" analyzed in this study.

Table 2. Summary of the analyzed "Struck By"

| No. | Activity | Accident | Consequences |

| 1 | Leak resistance test operation | Contact with a hard object (excavator bucket) | Death of 1 contractor |

| 2 | Pipeline troubleshooting | A worker is struck between the excavator bucket and the pipe |

Death of the worker responsible for the execution of the work |

| 3 | Daily visit operation of CGS station | Contact with a hard object (heater cap) | Death of 1 contractor worker |

| 4 | Insulation and sandblasting operations | A worker is struck between the sand (chain) of the side boom | Death of side boom operator |

| 5 | Pipe welding operation | Pipe falling on the worker | Death of 1 contractor worker |

| 6 | Channel digging operation to install a valve device | Contact with a hard object (excavator bucket) | Death of 1 worker |

| 7 | A process that provides assembly conditions for performing welding operations and the final connection of two pipelines | A worker is struck between the pipe and the bucket of the excavator | Death 1 welder |

| 8 | Pipe separation operation | A worker struck between pipes | Death of 1 loader driver |

In the leak resistance test accident, after finding the leak location, the contractor started digging with an excavator without draining or reducing the air pressure of the line. The excavator stops on the channel after digging. The worker with the excavator tries to empty the soil on the pipe with a hand shovel. Based on the investigation, it seems that the lack of welding of the welding head coupler related to the network valve and the presence of air pressure inside the network, with its sudden exit, led to the movement of the coupler from its place along with the production of noise and a lot of dust and sand spraying. Soil is the result of the release of energy. The victim is thrown to the back of the channel, exactly under the excavator bucket. The excavator driver directs the excavator bucket towards the bottom of the channel as a barrier in front of the cabin glass to prevent further damage and sand and dust splashing on the glass and dust entering the cabin. While he had no view of the inside of the channel, and for this reason, the bucket hit the body of the digger who was still inside the canal and directly under the shovel bucket.

In the pipeline troubleshooting accident, drilling operations are started to identify the location of the trouble. The person responsible for executing the work enters the channel by the excavator bucket to assist the technical inspection representative. The bucket shovel is also located inside the channel at a short distance from the mentioned one. The person in charge of executing the work uses an excavator bucket to get out of the channel. When the operator took the shovel out of the lock mode, the bucket of the shovel shook and hit the operator in the back, and he got struck between the bucket and the pipe.

In the daily visit operation of the CGS station accident, due to the accumulation of gas in the heater chamber, an explosion occurred, and the heater door was thrown due to the explosion and hit the contractor.

In the insulation and sandblasting operations accident, the side boom operator carries the air compressor by the side boom to the desired location of the sandblasting team. Due to the loosening of the balance weights, the operator hits the balance weights without stopping the machine. The side boom operator is dragged down the slope in the sand (chain) of the machine and dies.

In the pipe welding operation accident, after the completion of the drilling operation, the work is stopped due to lack of permission from the department. The work is stopped, and the workers leave the place, but the deceased was present at the place and did not leave the place and died when the pipe fell on him.

In the channel digging operation to install a valve device accident, Merlo machine and truck are sent to transport the deposited soil. With the opening of the bucket, the driver of the Merlo machine moves the soil from the side of the channel, when suddenly the bucket of the machine is separated and falls into the channel. A bucket falling and hitting the worker inside the channel will result in injury and death of the worker.

In the pipeline troubleshooting accident, drilling operations are started to identify the location of the trouble. The person responsible for executing the work enters the channel by the excavator bucket to assist the technical inspection representative. The bucket shovel is also located inside the channel at a short distance from the mentioned one. The person in charge of executing the work uses an excavator bucket to get out of the channel. When the operator took the shovel out of the lock mode, the bucket of the shovel shook and hit the operator in the back, and he got struck between the bucket and the pipe.

In the daily visit operation of the CGS station accident, due to the accumulation of gas in the heater chamber, an explosion occurred, and the heater door was thrown due to the explosion and hit the contractor.

In the insulation and sandblasting operations accident, the side boom operator carries the air compressor by the side boom to the desired location of the sandblasting team. Due to the loosening of the balance weights, the operator hits the balance weights without stopping the machine. The side boom operator is dragged down the slope in the sand (chain) of the machine and dies.

In the pipe welding operation accident, after the completion of the drilling operation, the work is stopped due to lack of permission from the department. The work is stopped, and the workers leave the place, but the deceased was present at the place and did not leave the place and died when the pipe fell on him.

In the channel digging operation to install a valve device accident, Merlo machine and truck are sent to transport the deposited soil. With the opening of the bucket, the driver of the Merlo machine moves the soil from the side of the channel, when suddenly the bucket of the machine is separated and falls into the channel. A bucket falling and hitting the worker inside the channel will result in injury and death of the worker.

Fig. 2. Tripod Beta diagram for ˈStruck By

Classification of Basic Risk Factors (BRFs) based on the Tripod Beta method: Table 3 shows the basic risk factors (BRFs) classification of analyzed accidents.

According to the Tripod Beta results (fig. 3), important potential risk factors for "Struck By" were identified. These factors include organizational factors (31.03%), work procedures (14.94%), tools and equipment

(11.5%), error enforcing conditions (10.35%), maintenance management (6.9%), design (6.9%), defenses (6.9%), communications (6.9%), training (4.6%) and incompatible goals (2.3%). More attention should be paid to organizational factors and work procedures to increase productivity and efficiency and prevent similar accidents.

According to the Tripod Beta results (fig. 3), important potential risk factors for "Struck By" were identified. These factors include organizational factors (31.03%), work procedures (14.94%), tools and equipment

(11.5%), error enforcing conditions (10.35%), maintenance management (6.9%), design (6.9%), defenses (6.9%), communications (6.9%), training (4.6%) and incompatible goals (2.3%). More attention should be paid to organizational factors and work procedures to increase productivity and efficiency and prevent similar accidents.

Table 3. Classification of basic risk factors based on the Tripod Beta method

| No. | Accident | Barriers | Underlying causes | Classification of underlying causes |

| 1 | Contact with a hard object (excavator bucket) | Creating warning signs, monitoring the competence of employees | Unlicensed contractor work, lack of command of excavators and manager's lack of awareness of job risks, weaknesses in monitoring systems, and complete non-compliance with principles | PR TR OR |

| Continuous supervision, safety training during work, compliance with work rules | Lack of necessary attention to the principles of safety and the employment of experienced workers, the speed of work, the type of contract based on the plan of gas supply | OR TR PR EC |

||

| 2 | Contact with a hard object (excavator bucket) | Using suitable means of transportation such as stairs or ladders | The equipment has been misused | TE |

| Incomplete equipment inspection | MM | |||

| Compliance with work rules, proper training of employees | The inappropriateness of testing the effectiveness of the given training | TR | ||

| Making decisions and issuing work permits based on work rules | Inadequate supervision to establish safe working conditions | OR | ||

| The inappropriateness of control systems within the company in terms of structure, resources, and methods | OR | |||

| Excavation safely and according to standards | The design does not meet industry standards | DE | ||

| 3 | Contact with a hard object (heater cap) | Periodic technical visits, revision, and modification of the instructions for setting up and decommissioning gas heaters | The last certificate of approval of the station heater by the technical inspection was valid until 1397 | PR OR |

| Failure to issue a work permit | PR OR |

|||

| The gas flow control system of heater number 1 is not in service | DF MM |

|||

| Not paying attention to the documentation of the gas supply manager regarding the action and the things to consider if the pilot flame and burner are off. | CO MM |

|||

| Failure to implement and run the preventive maintenance system | MM | |||

| Ineffective monitoring of the monitoring device | OR | |||

| There are no records of the visits made to the station, the contractor's daily visit control checklist, and the lack of documentation of Tool Box Meeting (TBM). | MM CO OR |

|||

| Effective training and retraining courses | Inadequacy of completed training courses with requested services and lack of retraining courses | TR | ||

| 4 | Sandblasting operations | Proper supervision and control and examination of work permits ,technical health of equipment, and competence of employees | Failure to obtain a work permit (PTW) for insulation work from the monitoring system | PR OR |

| Failure to obtain technical health certificate by side boom contractor | PR OR |

|||

| Carrying out activities on a slope of about 25% without complying with the relevant safety standards | DE DF |

|||

| Failure to control the competence of key project employees by the monitoring system | OR EC |

|||

| Obligation to comply with laws and training | Complete stop without turning off and standing on the (sand) chain of the side boom to fix the loose balance weights | DE TE MM EC IG DF |

||

| Incompetent machine operators | OR TE |

|||

| 5 | Pipe falling on the worker | Control, monitoring, use of warning signs and barriers | The poor performance of the monitoring device regarding issues such as the lack of restraints and alarms, not using proper cushions, observing the safe distance of the threaded pipes from the edge of the channel | EC OR DF |

| Failure to comply with the instructions and regulations related to excavation and piping | PR | |||

| Defects in project management and lack of proper coordination and notification with relevant companies to obtain work permits | OR CO |

|||

| Obligation to comply with laws and training | Not training workers about the risks associated with excavation and piping | TE | ||

| 6 | The excavator bucket fell and made contact with the worker | Control, supervision, and technical inspection of machines | Carrying out the simultaneous loading and transfer of the deposited soil by the transportation unit and the presence of the worker at a close distance to carry out the wall-building operation | DF OR EC CO |

| Lack of supervision of workers' activities | OR EC |

|||

| Failure to obtain permission to carry out work to carry out the work of building walls and transferring the deposited soil | OR PR |

|||

| Obligation to comply with laws and training | Failure to comply with safety regulations while doing work, especially in non-process and low-risk activities, simply because it is easy | OR PR TE |

||

| 7 | The welder is the impact between the pipe and the bucket of the excavator | Appropriate supervision ,control, and review of work permits | Failure to conduct adequate risk assessment and control, inspection, and audit in high-risk projects and operations | OR |

| Failure to conduct safety discussions at work by the contractor | OR CO |

|||

| Failure to prepare and communicate written instructions to perform Tie-in operations by the contractor and project manager | OR PR |

|||

| Not using the work permit to do work for Tie-in operation | OR PR |

|||

| Non-observance of safety measures during Tie-in operation | OR PR TE |

|||

| Obligation to comply with laws and training | Haste to do the work | IG TE |

||

| 8 | Pipe falling on the worker. | Supervision and control and appropriate program and provision of necessary equipment and work permit | Improper means of transporting pipes and defects in transportation and loading | DF TE DE |

| Lack of attention of the monitoring system to the regulations and inadequate monitoring | OR EC |

|||

| Failure to obtain a work permit | OR PR |

|||

| Lack of employer supervision and presence of HSE supervisor and representative | OR EC CO |

|||

| Obligation to comply with laws and training | Lack of proper training | TE | ||

| Working alone and not having a work permit | TE OR EC |

Fig. 3. Basic risk factors of accidents

Analyzing the accidents using the Bowtie method: Fig. 4 shows the Bowtie of analyzed accidents. Based on Figure 4, the most important causes of "Struck By" were brake cutting, driving unsafely, moving people out of the area where the machine is passing, getting people between the excavator and the pipe, contact with the heater cap and impact between the side boom chain and under the pipe and between the pipes.

Preventive safety barriers to prevent "Struck By"include checking equipment safety before starting work, installing warning barriers, checking employee certificates, creating safe routes for people, and assessing safety conditions before starting work. Preventive safety barriers are identified. Loss of life, money, and environmental damage are consequences of this event. Mitigating barriers to reducing the severity of consequences caused by a “Struck By” include the use of personal protective equipment and the presence of ambulances and paramedics at work. Each safety barrier created has an escalation factor, illustrated in Table 4.

Preventive safety barriers to prevent "Struck By"include checking equipment safety before starting work, installing warning barriers, checking employee certificates, creating safe routes for people, and assessing safety conditions before starting work. Preventive safety barriers are identified. Loss of life, money, and environmental damage are consequences of this event. Mitigating barriers to reducing the severity of consequences caused by a “Struck By” include the use of personal protective equipment and the presence of ambulances and paramedics at work. Each safety barrier created has an escalation factor, illustrated in Table 4.

Fig. 4. Bowtie diagram for "Struck By"

Table 4. Escalation factors of safety barriers in Bowtie diagram.

| Title | Bowtie's escalation factor diagram |

| Escalation factors of checking equipment safety before starting work |  |

| escalation factors of individual certification examination |  |

| escalation factors of installation of signs and warnings |  |

| escalation factors of creating a safe way for people to movement |  |

| escalation factors of safety assessment before starting work |  |

| escalation factors of Personal Protective Equipment (PPE) |  |

| escalation factors of the presence of ambulance and paramedics at the workplace |  |

| escalation factors of work permit issuance |  |

In general, escalation factors affecting the safety barriers, including supervision, HSE system, competency assessment, work permit system, risk management, contractor management, compliance with rules and guidelines, and training, were identified as the 8 escalation factors for "Struck By". These factors include several concepts, such as:

Table 5. Escalation factors in the Bowtie diagram

| No. | Escalation factors | Concepts |

| 1 | Supervision |

|

| 2 | HSE system |

|

| 3 | Work permit system |

|

| 4 | Competency assessment | Evaluating the competence of all employees and contractors |

| 5 | Risk management |

|

| 6 | Contractor management |

|

| 7 | Compliance with rules and guidelines |

|

| 8 | Training |

|

Discussion

Risk assessment and management of the gas industry are important due to the high-risk nature of these industries and the high capital values within them. Since the occurrence of accidents in these industries causes damage to production, human resources, equipment and materials, and the environment, and as a result, a large part of the national capital is lost, identifying and assessing risks is critical to safety and health. This is the first step in development. The first escalation factor identified in this study is risk management. Risk management should identify criteria and factors that can be used to reduce risk to acceptable levels. In other studies, risk management has been mentioned as an important factor in risk assessment. For example, in the study by Suda et al., risk management allows for the reliability of project design due to formal methods or procedures to approve any relevant project, and added value because it allows for high performance, efficient cost management, and meeting project deadlines [25]. The second escalation factor identified in this study is competency assessment. In other studies, such as the study of Iqbal et al., a lack of experienced owners or contractors in terms of quality and management skills, as well as a lack of clear definition of authority, discipline, ineffective management of project scope, and management responsibilities are key factors in project outcomes [26]. Supervision is the third escalation factor identified in accidents involving "Struck By". In other studies, management and supervision in manufacturing companies is too complicated and human resources have been recognized as the prominent assets of organizations. Within these pressured organizations and companies, there is a need for (and opportunity for) the supervision function to play a critical role in helping organizations navigate these transitions [27]. The work permit system is the fourth escalation factor in accidents involving "Struck By". In other studies, such as Reddy et al.'s study, the work permit system is an important factor in the risk assessment of industries. A permit-to-work document specifies the task to be performed, associated foreseeable hazards, and the safety measures. The permit-to-work system has been widely used to ensure safety during maintenance and/or construction activities in almost every major hazard industry worldwide [28]. Compliance with rules and guidelines is another escalation factor. In other studies, such as the study by Hopkins et al., risk management and rule compliance are mentioned and considered an important factor for promoting safety in hazardous industries [29]. The HSE system factor is one of the other escalation factors in the "Struck By". The definition of the decision criteria related to HSE must consider the requirements and policies of the organization responsible for the bidding process [30].

In a study by L Kraidi et al., the HSE system and compliance with rules and guidelines were identified as the third and fourth critical risk factors related to oil and gas pipeline projects in Iraq [31]. The training factor is one of the other escalation factors for "Struck By". Training is cited as an important factor in many studies. A study by Guo and her colleagues identified training as an important risk factor in oil and gas pipeline transportation [32]. Wang and Duan also mention this factor as an effective factor in evaluating oil and gas pipelines [33]. Srivastava and Gupta investigated training as one of the effective risk factors in gas and oil industry risk assessment [34]. Contractor management is one of the other escalation factors in incidents involving "Struck By". In other studies, such as

Schramm et al.'s study, to improve safety and preserve the environment, the management of contractors/suppliers is needed [35].

One of the limitations of this study is the incomplete reporting of some accidents and the lack of sufficient information.

One of the suggestions of this study for future studies is to use the data obtained in this study for further investigation and modeling of related accidents using different methods. It is also possible to investigate the related incidents on a wider level and for other countries, and the causes found will be more complete. Identifying and modeling the causes of accidents and safety barriers for other gas pipeline accidents is also possible. Also, this study can be done quantitatively using quantitative methods such as Bowtie.

Conclusion

Accidents involving "Struck By" are one of the most common accidents in gas pipeline excavation and piping operations. This study collected reports of "Struck By" accidents in gas pipeline excavation and piping operations. The causes of these 8 accidents were identified using the Tripod beta method. Organizational factors were identified as the most important risk factors, with a probability of 31.03%, and incompatible goals, with a probability of 2.3%, were identified as the least important factors in the occurrence of "Struck By" accidents. According to the Bowtie method findings, the most important causes of "Struck By" were brake cutting, driving unsafely, moving people out of the area where the machine is passing, getting people between the excavator and the pipe, contact with the heater cap and impact between the side boom chain and under the pipe and between the pipes. Preventive safety barriers to prevent "Struck By"include checking equipment safety before starting work, installing warning barriers, checking employee certificates, creating safe routes for people, and assessing safety conditions before starting work. Preventive safety barriers are identified. Loss of life, money, and environmental damage are consequences of this event. Mitigating barriers to reducing the severity of consequences caused by a "Struck By" include the use of personal protective equipment and the presence of ambulances and paramedics at work.

Acknowledgement

We would like to thank the experts who helped us in analyzing the accidents.

Conflict of interest

None declared.

Funding

This study was financially supported by Tarbiat modares University.

Ethical Considerations

All steps of this study were approved by Committee of Ethics of Tarbiat Modares University. The information related to the incident report was provided to the research team by the company where the study was conducted after coordination.

Code of Ethics

This study was approved by the Ethics Committee of Tarbiat Modares University with code IR.MODARES.REC.1400.295.

Authors' Contributions

Aida Naghshbandi: Project administration, Formal analysis, Writing-Original draft. Omran Ahmadi: Conceptualization, Methodology, Writing- Review & editing. Hasan AsilianMahabadi: Review & editing.

Risk assessment and management of the gas industry are important due to the high-risk nature of these industries and the high capital values within them. Since the occurrence of accidents in these industries causes damage to production, human resources, equipment and materials, and the environment, and as a result, a large part of the national capital is lost, identifying and assessing risks is critical to safety and health. This is the first step in development. The first escalation factor identified in this study is risk management. Risk management should identify criteria and factors that can be used to reduce risk to acceptable levels. In other studies, risk management has been mentioned as an important factor in risk assessment. For example, in the study by Suda et al., risk management allows for the reliability of project design due to formal methods or procedures to approve any relevant project, and added value because it allows for high performance, efficient cost management, and meeting project deadlines [25]. The second escalation factor identified in this study is competency assessment. In other studies, such as the study of Iqbal et al., a lack of experienced owners or contractors in terms of quality and management skills, as well as a lack of clear definition of authority, discipline, ineffective management of project scope, and management responsibilities are key factors in project outcomes [26]. Supervision is the third escalation factor identified in accidents involving "Struck By". In other studies, management and supervision in manufacturing companies is too complicated and human resources have been recognized as the prominent assets of organizations. Within these pressured organizations and companies, there is a need for (and opportunity for) the supervision function to play a critical role in helping organizations navigate these transitions [27]. The work permit system is the fourth escalation factor in accidents involving "Struck By". In other studies, such as Reddy et al.'s study, the work permit system is an important factor in the risk assessment of industries. A permit-to-work document specifies the task to be performed, associated foreseeable hazards, and the safety measures. The permit-to-work system has been widely used to ensure safety during maintenance and/or construction activities in almost every major hazard industry worldwide [28]. Compliance with rules and guidelines is another escalation factor. In other studies, such as the study by Hopkins et al., risk management and rule compliance are mentioned and considered an important factor for promoting safety in hazardous industries [29]. The HSE system factor is one of the other escalation factors in the "Struck By". The definition of the decision criteria related to HSE must consider the requirements and policies of the organization responsible for the bidding process [30].

In a study by L Kraidi et al., the HSE system and compliance with rules and guidelines were identified as the third and fourth critical risk factors related to oil and gas pipeline projects in Iraq [31]. The training factor is one of the other escalation factors for "Struck By". Training is cited as an important factor in many studies. A study by Guo and her colleagues identified training as an important risk factor in oil and gas pipeline transportation [32]. Wang and Duan also mention this factor as an effective factor in evaluating oil and gas pipelines [33]. Srivastava and Gupta investigated training as one of the effective risk factors in gas and oil industry risk assessment [34]. Contractor management is one of the other escalation factors in incidents involving "Struck By". In other studies, such as

Schramm et al.'s study, to improve safety and preserve the environment, the management of contractors/suppliers is needed [35].

One of the limitations of this study is the incomplete reporting of some accidents and the lack of sufficient information.

One of the suggestions of this study for future studies is to use the data obtained in this study for further investigation and modeling of related accidents using different methods. It is also possible to investigate the related incidents on a wider level and for other countries, and the causes found will be more complete. Identifying and modeling the causes of accidents and safety barriers for other gas pipeline accidents is also possible. Also, this study can be done quantitatively using quantitative methods such as Bowtie.

Conclusion

Accidents involving "Struck By" are one of the most common accidents in gas pipeline excavation and piping operations. This study collected reports of "Struck By" accidents in gas pipeline excavation and piping operations. The causes of these 8 accidents were identified using the Tripod beta method. Organizational factors were identified as the most important risk factors, with a probability of 31.03%, and incompatible goals, with a probability of 2.3%, were identified as the least important factors in the occurrence of "Struck By" accidents. According to the Bowtie method findings, the most important causes of "Struck By" were brake cutting, driving unsafely, moving people out of the area where the machine is passing, getting people between the excavator and the pipe, contact with the heater cap and impact between the side boom chain and under the pipe and between the pipes. Preventive safety barriers to prevent "Struck By"include checking equipment safety before starting work, installing warning barriers, checking employee certificates, creating safe routes for people, and assessing safety conditions before starting work. Preventive safety barriers are identified. Loss of life, money, and environmental damage are consequences of this event. Mitigating barriers to reducing the severity of consequences caused by a "Struck By" include the use of personal protective equipment and the presence of ambulances and paramedics at work.

Acknowledgement

We would like to thank the experts who helped us in analyzing the accidents.

Conflict of interest

None declared.

Funding

This study was financially supported by Tarbiat modares University.

Ethical Considerations

All steps of this study were approved by Committee of Ethics of Tarbiat Modares University. The information related to the incident report was provided to the research team by the company where the study was conducted after coordination.

Code of Ethics

This study was approved by the Ethics Committee of Tarbiat Modares University with code IR.MODARES.REC.1400.295.

Authors' Contributions

Aida Naghshbandi: Project administration, Formal analysis, Writing-Original draft. Omran Ahmadi: Conceptualization, Methodology, Writing- Review & editing. Hasan AsilianMahabadi: Review & editing.

References

1. Hämäläinen P, Takala J, Kiat TB. Global estimates of occupational accidents and work-related illnesses 2017. Bendemeer, Singapore: Workplace Safety and Health Institute; 2017.

2. Luo X, Li X, Goh YM, Song X, Liu Q. Application of machine learning technology for occupational accident severity prediction in the case of construction collapse accidents. Saf Sci. 2023;163:106138. [DOI]

3. Benavides FG, Benach J, Muntaner C, Delclos GL, Catot N, Amable M. Associations between temporary employment and occupational injury: what are the mechanisms? Occup Environ Med. 2006;63(6):416-21. [DOI] [PMID] [PMCID]

4. Wadsworth EJ, Simpson SA, Moss SC, Smith AP. The Bristol Stress and Health Study: accidents, minor injuries and cognitive failures at work. Occup Med (Lond). 2003;53(6):392-7. [DOI] [PMID]

5. Flin R, Mearns K, O'Connor P, Bryden R. Measuring safety climate: identifying the common features. Saf Sci. 2000;34(1-3):177-92. [DOI]

6. Akbari ME, Naghavi M, Soori H. Epidemiology of deaths from injuries in the Islamic Republic of Iran. East Mediterr Health J. 2006;12(3-4):382-90. [PMID]

7. Attwood D, Khan F, Veitch B. Can we predict occupational accident frequency? Process Saf Environ Prot. 2006;84(3):208-21. [DOI]

8. Woldesellasse H, Tesfamariam S. Risk analysis of onshore oil and gas pipelines: Literature review and bibliometric analysis. J Infrastruct Intell Resil. 2023;2(4):100052. [DOI]

9. Kekeç B, Bilim N, Bilim A. Occupational health and safety in excavation works. Paper presented at: The 3rd International Civil Engineering and Architecture Conference (CEAC 2023); 2023 Mar 17-20; Kyoto, Japan.

10. Ahmadi O, Mortazavi SB, Asilian Mahabadi H. Application and modification of the Tripod Beta method for analyzing the causes of oil and gas industry accidents. Int J Occup Saf Ergon. 2021;27(3):928-37. [DOI] [PMID]

11. Shafiei P, Jabbari M, Mirza Ebrahim Tehrani M. Cause–responsibility analysis of occupational accidents in an automotive company. Int J Occup Saf Ergon. 2023;29(1):99-108. [DOI] [PMID]

12. Almeida RS, da Silva FV, Vianna SS. Combining the bow-tie method and fuzzy logic using Mamdani inference model. Process Saf Environ Prot. 2023;169:159-68. [DOI]

13. Alencar MH. Risk identification and Bowtie analysis for risk management of subsea pipelines. Paper presented at: The 33rd European Safety and Reliability Conference; 2023 Sep 3-7; Southampton, United Kingdom.

14. Villa V, Paltrinieri N, Khan F, Cozzani V. Towards dynamic risk analysis: A review of the risk assessment approach and its limitations in the chemical process industry. Saf Sci. 2016;89:77-93. [DOI]

15. Pasman HJ, Jung S, Prem K, Rogers WJ, Yang X. Is risk analysis a useful tool for improving process safety? J Loss Prev Process Ind. 2009;22(6):769-77. [DOI]

16. Shannon HS, Mayr J, Haines T. Overview of the relationship between organizational and workplace factors and injury rates. Saf Sci. 1997;26(3):201-17. [DOI]

17. Ahmadi O, Mortazavi SB, Asilian Mahabadi H, Hosseinpouri M. Development of a dynamic quantitative risk assessment methodology using fuzzy DEMATEL-BN and leading indicators. Process Saf Environ Prot. 2020;142:15-44. [DOI]

18. Pasman H, Rogers W. Bayesian networks make LOPA more effective, QRA more transparent and flexible, and thus safety more definable! J Loss Prev Process Ind. 2013;26(3):434-42. [DOI]

19. Hovden J, Albrechtsen E, Herrera IA. Is there a need for new theories, models and approaches to occupational accident prevention? Saf Sci. 2010;48(8):950-6. [DOI]

20. Siler-Evans K, Hanson A, Sunday C, Leonard N, Tumminello M. Analysis of pipeline accidents in the United States from 1968 to 2009. Int J Crit Infrastruct Prot. 2014;7(4):257-69. [DOI]

21. OSHA Training Institute. Construction Focus Four: Struck‐By Hazards. Arlington Heights, Pennsylvania, United States: OSHA Directorate of Training and Education; 2011. [Report]

22. Gower-Jones AD, van der Graf GC. Experience with Tripod BETA accident analysis. Paper presented at: The SPE International Conference on Health, Safety, and Environment in Oil and Gas Exploration and Production; 1998 Jun 7-10; Caracas, Venezuela. [DOI]

23. Mohammad Fam I, Kianfar A, Faridan M. Application of tripod-beta approach and map–overlaying technique to analyze occupational fatal accidents in a chemical industry in Iran. Int J Occup Hyg. 2010;2(1):30-6. [Article]

24. Yu Q, Hou L, Li Y, Chai C, Yang K, Liu J. Pipeline Failure Assessment Based on Fuzzy Bayesian Network and AHP. J Pipeline Syst Eng Pract. 2022;14(1). [DOI]

27. Suda KA, Rani NSA, Rahman HA, Chen W. A review on risks and project risks management: oil and gas industry. Int J Sci Eng Res. 2015;6(8):938-43.

28. Iqbal MI, Isaac O, Al Rajawy I, Khuthbuddin S, Ameen A. Hazard identification and risk assessment with controls (Hirac) in oil industry–A proposed approach. Mater Today Proc. 2021;44(6):4898-902. [DOI]

29. Moazen Jamshidi MH, Rasli A, Yusof R. Essential competencies for the supervisors of oil and gas industrial companies. Procedia Soc Behav Sci. 2012;40:368-74. [DOI]

30. Reddy V, Reddy I. Study of electronic work permit system in oil and gas industry–Kuwait. Int J Innov Sci Eng Technol. 2015;2(4):533-7.

31. Hopkins A. Risk-management and rule-compliance: Decision-making in hazardous industries. Saf Sci. 2011;49(2):110-20. [DOI]

32. Haddad AN, da Costa BBF, de Andrade LS, Hammad A, Soares CAP. Application of fuzzy-TOPSIS method in supporting supplier selection with focus on HSE criteria: A case study in the oil and gas industry. Infrastructures (Basel). 2021;6(8):105. [DOI]

33. Kraidi L, Shah R, Matipa W, Borthwick F. Analyzing the critical risk factors associated with oil and gas pipeline projects in Iraq. Int J Crit Infrastruct Prot. 2019;24:14-22. [DOI]

34. Guo Y, Meng X, Wang D, Meng T, Liu S, He R. Comprehensive risk evaluation of long-distance oil and gas transportation pipelines using a fuzzy Petri net model. J Nat Gas Sci Eng. 2016;33:18-29. [DOI]

35. Wang X, Duan Q. Improved AHP–TOPSIS model for the comprehensive risk evaluation of oil and gas pipelines. Pet Sci. 2019;16:1479-92. [DOI]

36. Srivastava A, Gupta JP. New methodologies for security risk assessment of oil and gas industry. Process Saf Environ Prot. 2010;88(6):407-12. [DOI]

37. Schramm C, Meißner A, Weidinger G. Contracting strategies in the oil and gas industry. Pipeline Technol. 2010;2010(Special Edition):33-6.

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution 4.0 International License. |