BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

URL: http://johe.rums.ac.ir/article-1-388-en.html

Google Scholar

Accepted: 2020/09/2

ePublished: 2020/09/29

Introduction

Sawmilling is an operation in which wood is broken down and formed into different board sizes after passing through various machines at a sawmill plant. Different types of hazards in the sawmill industry include ergonomic hazards, physiological stress, environmental risks, air toxic emissions, noise, and hazards related to machinery use [1]. Ergonomic hazards mainly occur due to lifting heavy loads, molding logs, repetitive work, and awkward working postures. Sawmill workers generally perform strenuous tasks for a long period of time with a break taken during the working time. Thus, they are forced to carry many loads during their work schedule, which makes them suffer from work-related musculoskeletal disorders. Sawmilling is known to include a high level of manual material handling (MMH), which includes heavy loads, strong forces, awkward postures, and repetitive movements, which are responsible for WMSDs as well [2]. Musculoskeletal disorders (MSDs) affect the human musculoskeletal system, including body joints, ligaments, muscles, nerves, and tendons. These disorders are associated with specific workloads in the sawmill industry, which are caused by adverse static positions, high demands on hand movements, working with vibrating tools, and working with unsupported elevated arms [3, 4]. Musculoskeletal disorders (MSDs) usually occur due to heavy physical work, static working postures for a long duration, frequent bending, squatting, and twisting postures, manual material handling, and repetitiveness of work [5]. In the sawmill industry, workers repetitively perform massive manual tasks for a prolonged duration, which could lead to severe physical stress among them [6]. According to Das [7, 8], brickfield workers suffer from musculoskeletal pain due to working for a long period of time without meeting ergonomic requirements. MMH is a main causative factor in WMSDs, which is mainly associated in sawmilling. Excessive physical workloads, noise, and heat stress have been identified as factors exerting adverse health effects on sawmill workers. Besides, different types of health risk in sawmill along with unfavourable working condition, noise pollution, which affects human [9]. Due to the high level of MMH involved in sawmilling operations, workers are exposed to high levels of risk and physical workloads. Excessive physical workloads, noise, and heat stress have been identified as factors exerting adverse health effects among sawmill workers [1, 10].

Sawmillers generally perform several types of strenuous and physical activities, among which one could refer to carrying logs or timbers, lifting timbers, processing wood, molding timbers in saw fillers, stacking wood (loading and unloading wood), grinding saw blades, as well as picking and packing sawdust. During the sawmilling process, sawmill workers have to face a lot of problems. One of these problems during the processing and molding of timbers is their direct exposure to dust containing microorganisms, including fungi, toxins, and chemical substances, which could significantly affect human health [11]. Adverse environ mental and physical conditions affect health conditions among sawmill workers. In addition, sawmill workers perform several types of activities that could cause hearing loss. Boateng and Amedofu [12] reported noise-induced hearing loss (NIHL) among local sawmill workers.

This study mainly aims to find out the prevalence of musculoskeletal disorders among sawmill workers. In addition, it tries to determine causative factors of work-related musculoskeletal disorders and occupational health problems occurring during sawmill activities among sawmill workers. Besides, this study aims to analyze working postures among sawmill workers and also tries to determine preventive measures for occupational health hazards. In the end, this study tries to evaluate handgrip strength among sawmill workers with the elbow flexion at 90º and 180º and compare the handgrip strength of the participants with that of the control subjects when resting and shortly after work.

Materials and Methods

This cross‐sectional study was conducted in two stages at 21 sawmills located by the river side of Bhadrakali, a Hooghly district of West Bengal, India. In the first stage, a total of 179 sawmill workers were selected randomly. In the second one, after checking the inclusion and exclusion criteria as well as collecting informed consent forms from the final experimental selected subjects (sawmill workers), a cross‐sectional study was conducted at 21 sawmills located by the riverside of Bhadrakali, a Hooghly district of West Bengal, India. This cross-sectional study was performed in two stages. In the first stage, a total of 179 sawmill workers were selected randomly. In the second stage, after checking the inclusion and exclusion criteria as well as collecting the informed consent forms, the final experimental subjects (n = 135) were selected. The same selection procedure was adopted for the control subjects. In the end, 130 subjects were randomly selected for the controls, who were busy in household activities involving a minimum number of manual activities. The sawmill unit was randomly selected from the surrounding area. There were no subjects who would work for less than six months at the sawmill. The exclusion criteria included injured subjects and subjects who did not grant consent for participating in the study.

An anthropometer measured the height, and a weighing machine measured the mass of the sawmillers and control workers. The Body Mass Index (BMI) [13] of the exposed and control subjects were also measured as well. Before performing the survey, written permission was received from each of the sawmill owners and other subjects. In addition, ethical approval was collected from the Institutional Human Ethical Clearance Committee of the Indian Council of Medical Research Guidelines.

The Nordic musculoskeletal questionnaire (NMQ) [14] was applied to both groups, i.e. the sawmill workers and control subject. A Subjective assessment of musculoskeletal disorders was recorded by applied with modified NMQ, among the both groups of workers. The questionnaire includes some short questions that identified the workers' viewpoints, types of work, work duration, and pain felt in different body region.

Besides, a handgrip dynamometer was used to measure the handgrip strength of the sawmillers and differentiate the results with those of the controls. The sawmillers and the controls were instructed in a straight standing position with their sides not bending, their arms remain at their sides, without connecting their body, with the handgrip dynamometer handled at full force [15]. A dynamometer was used to carry out the measurement two times a day before and after to sawmill activities by the sawmillers at the elbow flexion of 90º and 180 º, for it has been observed that the maximum and minimum values of grip strength vary based on the elbow position [16].

In addition, a noise measuring instrument maker by the Lutron Electronics Enterprise (Taiwan) was used, which was kept 4 m away from the source of the noise and 1 m above the ground to measure the level of the noise generated during different activities at the sawmill. Besides, a lux meter (Lutron) was used for assessing the light or brightness level of different place at the two worksites, i.e. indoors and outdoors.

A two-tailed chi-square test was utilized to find if the test item had any significant association with the feeling of discomfort. In addition, to assess the relationship between various factors and the discomfort felt, their odds ratios (ORs) and 95% confidence intervals (CIs) were computed. Next, the computed χ2 was compared with critical χ2 values for the chosen level of significance (p < 0.05). Besides, statistical analysis was performed using Primer of Biostatistics Statistical Software (Primer of Biostatistics 5.0. Msi version).

Results

According to results of the present study, the experimental subjects, i.e. the sawmill workers, had an average working experience of more than 9 years, while the other group had an average experience in their work of more than 10 years. The daily work schedule included the mean duration of work, i.e. 9.8 and 7.0 hours per day for the sawmill workers and the other group, respectively, and the number of working days was 6 in both groups.

The result of Table 1 shows the discomfort feeling in different parts of the body among the sawmill workers and controls. The questionnaire stated that the sawmill workers felt maximum discomfort (pain) in the lower portion (91%) of the body subsequently the hands (80%), shoulders (76%), knees (64%), upper back (58%), wrists (36%), neck (33%), feet (29%), and elbows (28%). The discomfort (pain) feeling, felt by the sawmillers could have been caused due to the fact that they had to perform a constantly meticulous tasks at the sawmill, which could lead to the feeling of discomfort among them. The table 1 also showed that the sawmillers had a significantly higher prevalence of discomfort feeling (pain) than the controls in different body parts, including the neck (OR=21.16; p=0.000), shoulders (OR=77.27; p=0.000), elbows (OR=50.53; p=0.000), wrists (OR=17.94; p=0.000), hands (OR=61.0; p=0.000), upper back (OR=176.0; p=0.000), lower back (OR=37.3; p=0.000), knees (OR=7.02; p=0.000), ankles (OR= 5.67; p=0.000), and feet (OR=52.40; p=0.000).

Table 1. The feeling of discomfort in different parts of the body among the sawmill workers and the control group

|

Different body parts |

Sawmill workers |

Control subjects |

|

95% CI |

χ2 value |

P-value |

||

|

Neck |

45 (33%) |

03 (02%) |

21.16 |

6.37- 70.24 |

40.91 |

P<0.001 |

||

|

Shoulders |

102 (76%) |

05 (04%) |

77.27 |

29.10- 205.12 |

138.49 |

P<0.001 |

||

|

Elbows |

38 (28%) |

01 (00%) |

50.53 |

6.81-374.54 |

37.40 |

P<0.001 |

||

|

Wrists |

49 (36%) |

04 (03%) |

17.94 |

6.24 - 51.56 |

43.62 |

P<0.001 |

||

|

Hands |

108 (80%) |

08 (06%) |

61.0 |

26.58 – 139.94 |

143.75 |

P<0.001 |

||

|

Upper back |

78 (58%) |

01 (00%) |

176.52 |

23.96 – 1300.46 |

100.16 |

P<0.001 |

||

|

Lower back |

123 (91%) |

28 (22%) |

37.33 |

18.07 – 77.12 |

127.95 |

P<0.001 |

||

|

Knees |

86 (64%) |

26 (20%) |

7.02 |

4.03 – 12.22 |

50.06 |

P<0.001 |

||

|

Ankles |

11 (08%) |

02 (1.5%) |

5.67 |

1.23 – 26.13 |

4.86 |

P=0.027 |

||

|

Feet |

39 (29%) |

01 (01%) |

52.40 |

7.07 – 388.19 |

38.69 |

P<0.001 |

The results of this study show that the feeling of discomfort among the sawmill workers was especially high in the body region of Lower back (91%), Hands (80%), shoulders (76%). And knee (64%), which was significantly (P<0.001) high in compare to control subjects. Most of the workers at the sawmill reported the feeling of discomfort when lifting timbers (99%) followed by carrying logs or timbers (98%), processing timbers (76%), moulding timbers in saw fillers (65%), stacking timbers (58%), grinding saw blades (32%), picking and packing saw dust (56%), etc. The results of the study also indicate that due to MMH and working in an inconvenient posture for long time span, the sawmillers felt pain in the different body parts. In addition, the discomfort feeling in the body was significantly difference (p < 0.001) in the experimental group than the controls.

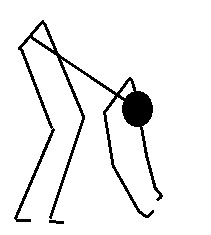

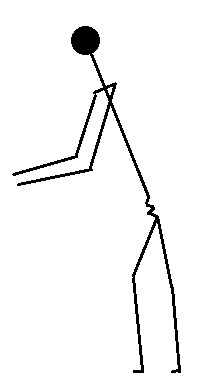

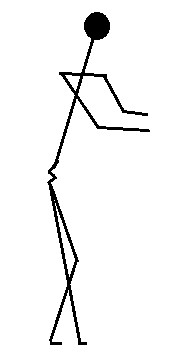

The result of table 2 shows that 282 sample postures collected and analysed from video analysis (Sony Handycam) were used by the 135 sawmill workers. In addition, the results (Table 5) indicate that OWAS action category 4 (corrective measures required immediately) had the highest number of postures (51.1%) followed by action category 3 (corrective measures required as soon as possible) (42.9%). Besides, only 3.9% of the sawmillers postures considered into action category 2 (corrective actions required in the near future), and only 2.1% of the sawmiller postures considered into action category 1 (no corrective measures required). Table 2 shows the results of posture analysis by the OWAS method. The table 2 shows that most of the sawmill activities (lifting timbers, carrying logs or timbers, moulding timbers, and picking saw dust) need strenuous postures (OWAS action category 4), which requires adopting immediate corrective measures. Besides, activities like grinding saw blades and stacking timbers require corrective posture measures as soon as possible (OWAS action category 3).

Table 2. Analysis of different working postures of the sawmill workers by the OWAS method

|

|

Stick diagram |

Posture |

|

Action category |

Remarks |

|

Lifting timbers |

|

Back bent forward and twisted, both arms below the shoulder level, both knees bent, a weight of 10 kg or less |

4141 |

4 |

Immediate corrective measures |

|

Carrying logs or timbers |

|

Back bent forward/ backward, both arms above the shoulder level, walking or moving, a weight or force needed to be over 20 kg |

2373 |

4 |

Immediate corrective measures |

|

Moulding timbers |

|

Back bent forward, both arms below the shoulder level, |

2153 |

3 |

Corrective measures needed as soon as possible |

|

Moulding timbers |

|

Back bent backward and twisted, both arms below the shoulder level, |

4143 |

4 |

Immediate corrective measures |

|

Grinding saw blades |

|

Back bent forward, both arms below the shoulder level, |

2151 |

3 |

Corrective measures needed as soon as possible |

|

Stacking timbers |

|

Back bent forward, both arms below the shoulder level, |

2153 |

3 |

Corrective measures needed as soon as possible |

|

Picking saw dust |

|

Back bent forward and twisted, both arms below the shoulder level, |

4141 |

4 |

Immediate corrective measures |

According to the results of this study, the resting handgrip strength values (MVC values) at the elbow flexion of 90º flexion and 180º flexion among the sawmill workers were 41.88 (±4.28) and 39.90 (±3.98), respectively (Table 3). In addition, the handgrip strength values at the elbow flexion of 90º and 180º were 36.20 (±2.34) and 35.12 (±2.35), respectively. The resting handgrip strength value (MVC value) at the elbow flexion of 90º and 180º among the control subjects was 40.98 (± 3.32), whereas the control subjects’ handgrip strength value just after the completion of work was 37.25 (± 2.36) at the elbow flexion of 90º and 36.88 (± 2.68) at the elbow flexion of 180º (p<0.05). This study also revealed a significant change in the handgrip strength value measured at the elbow flexion of 90º and 180º between the resting condition (MVC values) and just after the completion of work among the saw millers. At the elbow flexion of 90º in the resting condition, the sawmill workers had a higher handgrip strength than the controls; however, soon after the completion of work, there was a significant decrease in the handgrip strength among the sawmillers compared to the controls.

Table 3. The relationship between the handgrip strength (in kg) of the sawmill workers and that of the control subjects

|

Handgrip strength |

Different conditions |

Sawmill workers |

Control subjects |

F-value |

P-Value |

|

|

At the elbow flexion of 90º |

Resting |

41.88 (± 4.28) |

40.98 (± 3.32) |

3.64 |

P=0.058 |

|

|

Just after work completion |

36.20 (± 2.34) |

37.25 (± 2.36) |

13.22 |

P<0.001 |

||

|

At the elbow flexion of 180º |

Resting |

39.90 (± 3.98) |

40.98 (± 3.32) |

5.73 |

P=0.017 |

|

|

Just after work completion |

35.12 (± 2.35) |

36.88 (± 2.68) |

32.37 |

P<0.001 |

||

The present study showed that the sawmill workers performing their work in an unfavourable condition. The average value of the indoor WBGT index at the sawmill was 34.5 °C with the relative humidity of 76%. Besides, the average noise level was 98 dB (A) during the timber or log cutting process. Moreover, the log dust emitted could affect the saw millers. Since the saw millers were of low socioeconomic status, they sometimes had to work at night under poor illumination conditions (M 13.28 lx).

According to the results of the questionnaires used in this study (Fig. 1), apart from the feeling of discomfort, most of the sawmill workers suffered from difficulties in breathing (94%), eye irritation (62%), skin irritation (60%), noise irritation (55%), cardiovascular problems (42%), gastrointestinal problems (40%), and electric shocks (12%).

.jpg)

Fig. 1. Work-related health problems among sawmill workers and control subjects

Discussion

The prevalence of occupationally health risk assessment has been reported to be high among the Indian. Sawmill workers are faced with several types of health problems in their daily life. During sawmill activities, sawmillers carry out several types MMH tasks that could be resourceful factors for the development of MSDs among them. The current study dealt with MMH among sawmill workers who had to lift and carry heavy loads (logs), which may be a causative factor in musculoskeletal disorders. Data analysis results showed a significant relation between the feeling of discomfort among the sawmill workers and the control group. Besides, the present study indicated that the sawmillers were mainly engaged in hand-intensive tasks and had to perform strenuous work with repetitiveness throughout the day; thus, they suffered most, whereas the workers of the controls performed comparatively less strenuous activities and suffered least.

Based on the current study observation of working conditions among the sawmillers, it was evident that the sawmillers worked under unfavourable conditions because they had to lift loads and carry weights (logs). This could cause a feeling of discomfort in different region of the body, especially in the low back (91%), hands (80%), shoulders (76%), knees (64%), upper back (58%), wrists (36%), and the neck (33%). The current study shows that as the sawmill workers perform heavy tasks most often in unusual postures, which may the main leading factors of MSDs especially in the lower region of their body. Similar results have been obtained by other researchers in other sectors. Gangopadhyay et al [17] and Goldsheyder et al [18] indicated that working in an unusual, squatting and forward bending posture and MMH were the main causative factors in the LBP among sawmillers. Additionally, they stated that LBP constituted a significant problem in the construction industry. According to Pope [19], frequently found lower back and lower limb disorders, immensely among the construction workers, and Das [20, 21] made a similar observation among workers in the field of railway track maintenance and manual brick manufacturing works.

Musculoskeletal disorders (MSD) have been known to be connected with the MMH, and working in an unusual and awkward postures for long time at a stretch in a repetitive manner [22, 23, 24]. Awkward flexion as well as twist and bending laterally are significantly related to LBP [25]. The load affects the lumbar region, which in turn affects muscle loading and compressive forces on the intervertebral disc [26]. Thus, low-back problems have been mainly found out to be associated with the types of postures requiring back flexion, the carrying and lifting of heavy loads, and exposure to whole-body vibration [27]. Physically demanding tasks and the different stress factors, including poor unusual working postures and the activities, which are mainly familiar with use of force, are found among sawmillers. The National Institute of Occupational Safety and Health (NIOSH), in a review of a MSDS-related work, found strong evidence indicating that lower back disorders are caused by forceful manual lifting and MMH [28].

In the current study, the handgrip strength of exposed workers and controls were measured at the of 90° and 180° elbow flexion. Accordingly, a significant change has been found in the handgrip strength in just after work condition between the sawmill workers and the control group. The results indicates that, sawmillers were continuously engaged in hand-intensive tasks, that would be damaged and suffered by the pain feeling in the upper parts of the body and significant changes in the hand-grip strength. Similar results were obtained by Gangopadhyay and his colleagues [29] and Das [30]. They stated that the handgrip strength value of the sawmillers was lower than that of the control subjects just after work at the elbow flexion of 90° and 180°. The handgrip strength was measured primarily to draw a correlation with the back, neck, and shoulder pain. According to Chandra et al [31], handgrip measurements of sawmill workers indicated that the lowered the handgrip strength may be connected to the increased loading at the proximal end; in other words, cervical spine muscles and shoulder joints muscles might have to apply greater strength to control arm movements. It was observed, in the current study, that the significant change in the handgrip strength between the sawmillers and the comparison group. Besides, it was found out that the sawmill workers do their work in a difficult and unusual postures at work, by which they experienced MSDs, because they remained in such difficult and unusual positions for prolonged periods. Forward bending work postures influence vertebral discs, and the affected spine is the area of the LBP, with other musculoskeletal symptoms being serious problems among sawmill workers.

Based on the examination of the current study, it was evident that the sawmill workers performed their work in a poorly illuminated (13.28 lx) congested working area because most of the workstation was located indoors and entirely covered with asbestos and tin to protect logs or timbers against rainwater, where the illumination level was poor. In addition, the sound level at the time of cutting the sawn woods in the workstation was very high (104 dB (A)), which could affect the sawmill workers. Besides, it was evident that the sawmill workers suffered from a high level of noise during the processing and moulding of timbers, which affected their health seriously. Noise-induced hearing loss is a serious public health concern in many developing countries, like India. Occupational noise remains a causative factor in industrial diseases [32]. Sound is one of the probable factors in causing sleep disruption, cardiovascular abnormalities, and mental health disorders, including hearing and balance disorders [33]. Prolonged exposure to high noise levels (greater than 80dB) could lead to hearing loss [34].

Possible preventive measures to help reduce health risks among sawmill workers include:

1. Proper operator training, knowledge, and education should be provided to sawmill workers to improve their health and avoid accidents.

2. Manual material handling (MMH) should be avoided, which is the most critical causative factor in musculoskeletal disorders (MSD) among sawmill workers.

3. Job rotation should be considered among sawmill workers.

4. Sawmillers should change their posture frequently to circumvent from the feeling of discomfort.

5. They are recommended to improve their work programme by taking more rest break time to circumvent excessive bodily stress.

6. Different types of physical exercises should be taken during break time.

7. Personal protective equipment (earplugs or muffs) should be used during the moulding operation or when preparing sawn woods or timbers to reduce the noise that aggravates physiological parameters (heart rate and blood pressure) among sawmill workers.

9. Eyeglasses, nose masks, and helmets should be used when moulding or processing sawn woods or timbers.

10. Body fluid replacement must be done to avoid in a high thermal load.

Conclusion

Conclusions drawn from the current study include:

i) The current study mainly indicated that sawmillers had MSDs especially in the upper parts and the low back of their body due to involve in working with difficult postures for an long time period and because of MMH.

ii) One of the findings of this study was that the sawmill workers had a strong handgrip due to carry out more arduous hand-intensive tasks than the controls.

iii) The noise produced at the sawmill during the processing of timbers is very harmful to sawmill workers.

iv) OWAS posture analysis showed that 51.1% of the postures required immediate corrective measures (OWAS Action Category 4), whereas 42.9% of the working postures of the sawmill workers required corrective measures as soon as possible.

Acknowledgement

The author would like to extend his heartfelt gratitude to all sawmillers, control subjects, and sawmill owners who participated in the study.

Conflict of interest: None declared.

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution 4.0 International License. |