Volume 11, Issue 1 (Winter 2022)

J Occup Health Epidemiol 2022, 11(1): 32-40 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Hasheminejad N, Zare A, Farahbakhsh S, Bamir M, Zolala F. Hazard Identification and Risk Assessment of Occupational Activities in Golgohar Mining Company, Southeast Iran (2021). J Occup Health Epidemiol 2022; 11 (1) :32-40

URL: http://johe.rums.ac.ir/article-1-449-en.html

URL: http://johe.rums.ac.ir/article-1-449-en.html

Related article in

Google Scholar

Google Scholar

Similar articles

1- Associate Prof., Dept. of Occupational Health, School of Health, Kerman University of Medical Sciences, Kerman, Iran.

2- Assistant Prof. of Occupational Health Engineering, Dept. of Occupational Health, Sirjan School of Medical Sciences, Sirjan, Iran.

3- Master of Occupational Health, Dept. of Occupational Health, Sirjan School of Medical Sciences, Sirjan, Iran. ,bamir@gmail.com

4- PhD Student in Medical Librarianship, Social Determinant of Health Research Center, Institute for Future Studies in Health, Kerman University of Medical Sciences, Kerman, Iran.

5- Associate Prof. Epidemiology, Regional Knowledge Hub for HIV/AIDS Surveillance, Institute for Futures Studies in Health, Kerman University of Medical Sciences, Kerman, Iran.

2- Assistant Prof. of Occupational Health Engineering, Dept. of Occupational Health, Sirjan School of Medical Sciences, Sirjan, Iran.

3- Master of Occupational Health, Dept. of Occupational Health, Sirjan School of Medical Sciences, Sirjan, Iran. ,

4- PhD Student in Medical Librarianship, Social Determinant of Health Research Center, Institute for Future Studies in Health, Kerman University of Medical Sciences, Kerman, Iran.

5- Associate Prof. Epidemiology, Regional Knowledge Hub for HIV/AIDS Surveillance, Institute for Futures Studies in Health, Kerman University of Medical Sciences, Kerman, Iran.

Article history

Received: 2021/08/2

Accepted: 2022/03/7

ePublished: 2022/03/25

Accepted: 2022/03/7

ePublished: 2022/03/25

Subject:

Occupational Health

Keywords: Risk Assessment [MeSH], Mining [MeSH], Hazard Management [MeSH], Occupational Health [MeSH]

Full-Text [PDF 374 kb]

(1972 Downloads)

| Abstract (HTML) (4675 Views)

Table 1. Demographic information of the studied population (n = 763)

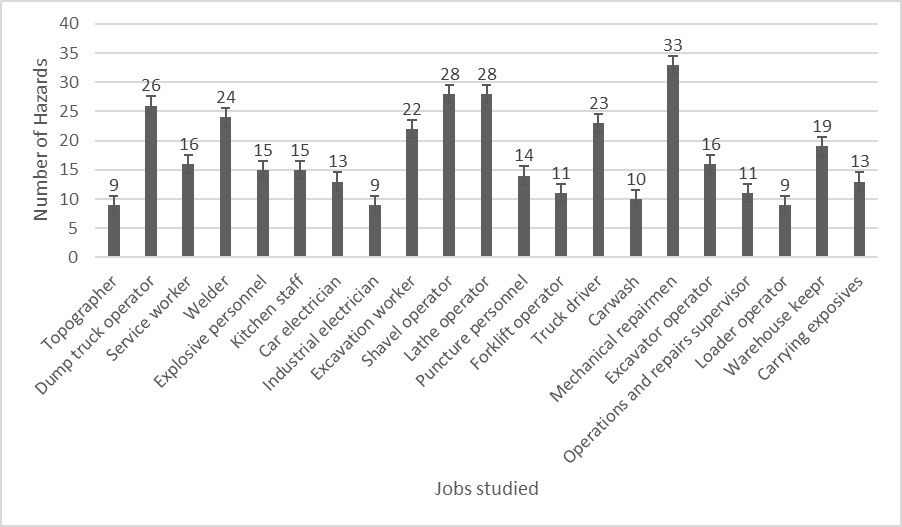

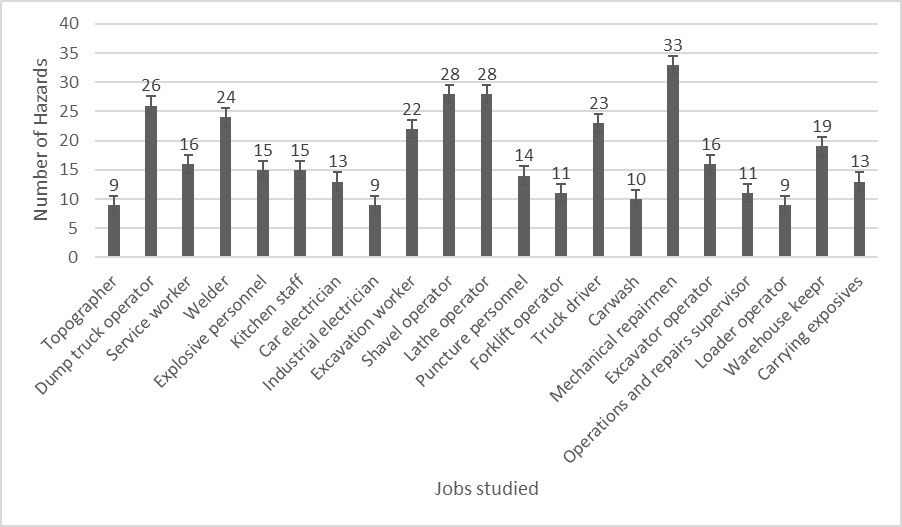

Fig. 1. Hazards identified in the JSA method for different jobs

Fig. 2. Frequency of hazards identified by the JSA method

Table 2. Risk assessment of high-risk jobs in mine no. 1 of Golgohar Industrial Mining Company in Sirjan

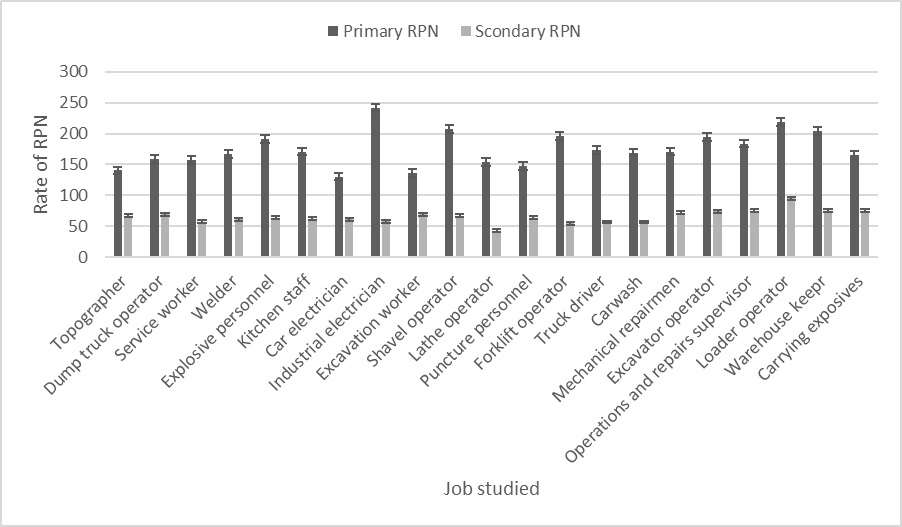

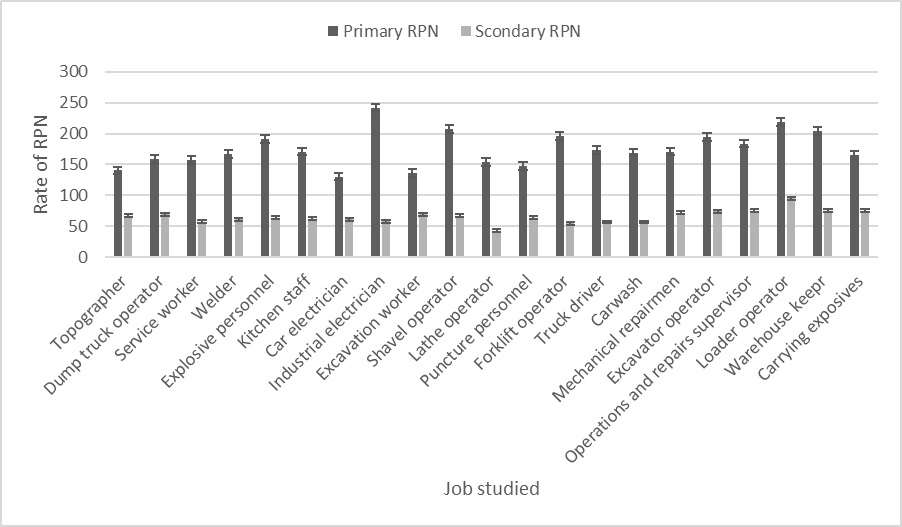

Fig. 3. RPNs of the studied jobs before and after the intervention

Discussion

According to Rison's study, unlike obvious errors (especially human errors), latent conditions can be identified and corrected before unfortunate events occur. Understanding this theory facilitates error detection on the way to prospective risk management instead of retrospective risk management [23]. In this regard, hazards in different jobs of the mine were identified by JSA, and their risk level was calculated using FMEA as mentioned earlier; in addition, RPN 100 was considered as the acceptable risk criterion.

As expected, all mining jobs had high and unacceptable risks. The highest number of risks was related to mechanical repairmen, and the lowest numbers of risks were related to loader operators, topographers, and industrial electricians. According to the results, before applying control suggestions, the occupational group of industrial electricians and car electricians had the highest and lowest risk priority numbers, respectively. In addition, after applying control suggestions, loader operators and lathe operators had the highest and lowest risk priority numbers, respectively. In line with the results of the present study, Koohnavard et al reported that the majority of identified hazards were observed in the mechanical unit of Iran Khodro Company [24]. In the study of Permana et al, risk assessment was performed, in which the major source of mine accidents was found to be tools, and the major mine accident locations were the mechanic’s workshop and the mine pit [25]. Based on Onder’s study, the largest proportion of accidents causing injuries occurred by mining machines (39.2%), and other reasons were general machinery (25%), manual and mechanical handling (16.7%), hand tools (11.9%), and getting hit by or falling of objects (7.2%). Besides, maintenance personnel (79.4%) were more likely to get injured than workers (11.7%) and drivers (8.9%) [26].

Based on JSA results, the throwing and falling of objects, slipping and falling from heights, vehicle accidents, as well as dust inhalation and pollution were the most likely hazards in the mine studied. Consistent with the present study, in the study of Ebrahimzadeh et al (2015), rock falls were identified as the major hazard in a uranium mine [27]. Rudakov stated that despite the general desire for reducing the number of fatal injuries among miners, the method of assessing the risk of rock falls needs to be improved, with this problem in mines being always one of the most likely accidents [28]. Work accidents, when conducting mining activities, often occur due to unsafe field conditions. In open mine areas, there is often a slump due to unstable slopes, which can disrupt the activities and productivity of mining companies, thereby causing the falling of workers or objects [29]. Munirwansyah et al showed that slopes in open pit mines require careful engineering to reduce accident potentials [29]. However, the results of a review study by Duarte et al showed that trucks, dump trucks, and conveyors were devices with greatest impacts on accident rates in mines [30].

Exposure to airborne contaminants in the mining process can lead to pulmonary and respiratory disorders among miners [31-33]. In an epidemiological study, production of large amounts of airborne dust during mining operations was known to increase the mortality rate due to lung cancer among the population of suburban residents [34]. In the study of Safinejad et al, exposure of workers at the Sirjan Golgohar iron ore mine to dust and insoluble iron compounds exceeded the recommended standard (5 mg/m3) set by the Center for Environmental and Occupational Health of Iran and ACGIH [35]. In the study of Gholami et al on airborne dust at Sangan mine in Khaf City, concentrated inhalable dust was reported to be more than the recommended standard [36]. Inconsistent with the present study, studies in the United States and Sweden reported that the rate of dust inhalation in iron mines was satisfactorily low due to the availability of optimal industrial ventilation systems [37, 38]. Biological monitoring, as the best way for assessing occupational exposure, has in recent years attracted the attention of many researchers and has been considered an alternative for comparing the level of exposure of individuals, according to occupational standards [39, 40].

Heavy machinery is considered one of the major contributors to accidents in this industry [30]. Given high work demands, work pace control, and heavy workloads, operators do not have enough knowledge and ignore safety [41, 42]. Failure to fasten seatbelts was associated with several loader and truck accidents [43]. Being inattentive to safe working procedures or standard operating procedures, as well as unsafe or careless actions could be the cause of work-related accidents [25]. In addition, failure to recognize adverse geological conditions, respect the loader’s working area, and maintain adequate berms, as well as the lack of warning signs and appropriate mine maps, inadequate provision of safety levels, and failure to adapt to poor weather conditions were all worker behaviors posing a significant threat [44]. Losing control of equipment has been reported as the leading cause of machine-related fatalities in surface mining [45]. Based on some studies, occupational groups having the highest percentage of all accidents in mines were maintenance personnel and mechanic repairmen [26, 46, 47]. Groves et al [48] showed that a significant portion (54%) of accidents in the mining industry was due to material handling, machinery (12%), hand tools (11%), roof falls (10%), and powered haulage (8%).

In this study, high risk levels accounted for 59% of all identified risks that needed to be corrected immediately, and 35% of the identified risks had moderate risk levels that needed to be reduced. After the interventions, the risks identified at high and medium levels were 4 and 30%, respectively, which indicated the positive effect of the suggestions on reducing risk levels of the studied jobs. Based on the literature review, the types of activities most often associated with injuries in mining had not changed much. In addition, despite various realities in different countries studied, the number of accidents was higher than expectations. Equipment contributing most to work-related accidents included haul trucks, dumpers, and conveyors, especially during maintenance operations.

The limitation of the present study was that it was done on one mine, so it is suggested to be repeated in similar mines and other mines of Golgohar Company.

Conclusion

In this study, high-risk jobs and significant work-related hazards were identified in a mine. As can be seen, control suggestions, such as improving safe operation conditions, training workers, and using protective equipment were able to reduce hazards in all jobs. Constant identification and control of mining hazards should be considered necessary measures for preventing accidents as well as monitoring and controlling equipment operations effectively. In addition, compliance with rules and regulations should be coincided with training and education, with special attention to be given to less experienced workers who are more vulnerable to equipment-related accidents. Besides, educational programs should include ergonomics of carrying objects manually, careful use of hand tools, and importance of using personal protective equipment. Furthermore, factors, such as training and competence assurance management of fatigue-induced errors as well as control of workloads could eliminate some errors leading to accidents. Additionally, manufacturers should improve equipment safety and protective devices at some entry points to protect workers from getting caught in or rolled up in machinery during operations. Careful job planning and effective communication about tasks could help avoid most accidents.

Acknowledgement

The authors would like to extend their thanks to all participants for their support and assistance. They would also like to thank Sirjan School of Medical Sciences for supporting this project (No. 20834).

Conflict of interest: None declared.

Full-Text: (1029 Views)

Introduction

At present, many jobs and processes are considered critical, for any errors associated with them can have catastrophic consequences, such as deaths, severe economic damage, and widespread environmental pollution [1, 2]. The mining industry is one of the most critical industries. According to surveys, due to the nature of mining, mines are among the most dangerous and accident-prone environments in which workers face death or disability [3-6]. According to the Occupational Safety and Health Administration (OSHA), 113 fatal accidents were reported in mines from 1995 to 2006. Statistics in 2017 showed that the total number of operative mines in Iran was 5,214, and the average number of miners employed was 91,211. In 2015, 317 mines in Iran were involved in accidents. Accordingly, A total of 1,510 accidents occurred in these mines, and 1,589 workers were injured, of whom 28 died [7].

Past research cited specialized and basic causes for accidents in the mining industry. In the study of Javadi et al (2016) on the Tabas coal mine, falling on the roof of the extraction workshop and falling in the corridors of the extraction zones were identified as the major hazards in that mine [8]. Zhang et al (2016) concluded that the three factors affecting mining accidents included the lack of safety training, mining safety liability rules and regulations, as well as monitoring and inspection rules and regulations [9].

Risk assessment is one of the fundaments of safety management, with its objective being to identify, evaluate, and control risk factors affecting employee health and safety in the industry [10, 11]. There are different methods for identifying hazards, which can be employed depending on the stage of the process development in the system life cycle, system complexity, process type, organizational culture, workers' experience, and expertise of the hazard identification team members [12, 13]. Job safety analysis (JSA) is one of the methods through which risk assessment can be performed for activities and occupations. In fact, JSA is a method of studying jobs accurately and regularly to identify and assess existing or potential risks in each process or job. In this method, the job is broken down step by step; next, the risks of each step are identified, and control solutions are provided in the end. The main objective of this method is to find a safe way to do things and prevent related accidents. In addition, using this method, it is possible to understand what is needed in training employees. Besides, JSA can be used to develop a safety management and

accident prevention program [14]. The failure modes and effects analysis (FMEA) technique was introduced as a valid technique among risk analysis techniques [15]. The purpose of the FMEA technique is to prevent accidents in a process. In other words, through optimizing processes and products, it causes a significant reduction in material damage and human injuries caused by unwanted accidents. Since suggestions and corrective actions are presented in the early stages of process development in this method, changes are relatively simple and inexpensive [16, 17]. As a result, there is a robust process without critical conditions, which probably does not need to be gone through until the end of the system life cycle [9].

Due to the abundance of mineral resources in Iran and the high number of workers in the mines, it is necessary to study occupational hazards in the mining industry [18]. Given the size and importance of the Golgohar Mining Company in Sirjan City, this study aims to investigate occupational hazards and perform a risk assessment in Golgohar mine no. 1. In the present study, JSA and FMEA methods were used to identify risks and rank risk levels.

Materials and Methods

A descriptive study was conducted on the Golgohar Mining Industrial Company in Sirjan city, Kerman Province, 2020. Sampling was performed through a census and all 763 workers of the mine were invited (Table 1). This article was extracted from a master's thesis.

At present, many jobs and processes are considered critical, for any errors associated with them can have catastrophic consequences, such as deaths, severe economic damage, and widespread environmental pollution [1, 2]. The mining industry is one of the most critical industries. According to surveys, due to the nature of mining, mines are among the most dangerous and accident-prone environments in which workers face death or disability [3-6]. According to the Occupational Safety and Health Administration (OSHA), 113 fatal accidents were reported in mines from 1995 to 2006. Statistics in 2017 showed that the total number of operative mines in Iran was 5,214, and the average number of miners employed was 91,211. In 2015, 317 mines in Iran were involved in accidents. Accordingly, A total of 1,510 accidents occurred in these mines, and 1,589 workers were injured, of whom 28 died [7].

Past research cited specialized and basic causes for accidents in the mining industry. In the study of Javadi et al (2016) on the Tabas coal mine, falling on the roof of the extraction workshop and falling in the corridors of the extraction zones were identified as the major hazards in that mine [8]. Zhang et al (2016) concluded that the three factors affecting mining accidents included the lack of safety training, mining safety liability rules and regulations, as well as monitoring and inspection rules and regulations [9].

Risk assessment is one of the fundaments of safety management, with its objective being to identify, evaluate, and control risk factors affecting employee health and safety in the industry [10, 11]. There are different methods for identifying hazards, which can be employed depending on the stage of the process development in the system life cycle, system complexity, process type, organizational culture, workers' experience, and expertise of the hazard identification team members [12, 13]. Job safety analysis (JSA) is one of the methods through which risk assessment can be performed for activities and occupations. In fact, JSA is a method of studying jobs accurately and regularly to identify and assess existing or potential risks in each process or job. In this method, the job is broken down step by step; next, the risks of each step are identified, and control solutions are provided in the end. The main objective of this method is to find a safe way to do things and prevent related accidents. In addition, using this method, it is possible to understand what is needed in training employees. Besides, JSA can be used to develop a safety management and

accident prevention program [14]. The failure modes and effects analysis (FMEA) technique was introduced as a valid technique among risk analysis techniques [15]. The purpose of the FMEA technique is to prevent accidents in a process. In other words, through optimizing processes and products, it causes a significant reduction in material damage and human injuries caused by unwanted accidents. Since suggestions and corrective actions are presented in the early stages of process development in this method, changes are relatively simple and inexpensive [16, 17]. As a result, there is a robust process without critical conditions, which probably does not need to be gone through until the end of the system life cycle [9].

Due to the abundance of mineral resources in Iran and the high number of workers in the mines, it is necessary to study occupational hazards in the mining industry [18]. Given the size and importance of the Golgohar Mining Company in Sirjan City, this study aims to investigate occupational hazards and perform a risk assessment in Golgohar mine no. 1. In the present study, JSA and FMEA methods were used to identify risks and rank risk levels.

Materials and Methods

A descriptive study was conducted on the Golgohar Mining Industrial Company in Sirjan city, Kerman Province, 2020. Sampling was performed through a census and all 763 workers of the mine were invited (Table 1). This article was extracted from a master's thesis.

Table 1. Demographic information of the studied population (n = 763)

| Job | N | Age (year) Mean (SD) |

Work experience (year) Mean (SD) |

Job | N | Age (year) Mean (SD) |

Work experience (year) Mean (SD) |

| Dump truck operator | 190 | 34.4 (3.1) | 10.2 (3.2) | Operation and repair supervisors | 25 | 38.6 (4.1) | 15.6 (3.6) |

| Mechanical repairman | 114 | 31.7 (1.2) | 6.2 (4.9) | Carwash personnel | 31.3 (5.6) | 10.3 (4.6) | |

| Service worker | 60 | 37.4 (3.5) | 11.6 (5.2) | Loader operator | 15 | 39.4 (5.3) | 16.7 (2.7) |

| Welder | 51 | 40.7 (2.7) | 13.5 (7.4) | Operator shavel | 15 | 36.8 (3.4) | 14.6 (8.2) |

| Explosive personnel | 47 | 29.2 (5.8) | 6.2 (3.6) | Lathe operator | 14 | 41.3 (5.8) | 20.5 (5.9) |

| Kitchen staff | 39 | 43.1 (4.1) | 19.3 (7.5) | Warehouse keeper | 11 | 33.4 (1.5) | 11.3 (2.8) |

| Excavator operator | 30 | 29.7 (4.9) | 6.9 (4.6) | Puncture personnel | 8 | 36.1 (4.5) | 13.6 (3.6) |

| Car electrician | 27 | 28.5 (5.1) | 6.3 (2.9) | Topographer | 7 | 35.2 (7.4) | 13.2 (7.5) |

| Industrial electrician | 25 | 33.5 (8.2) | 11.4 (3.6) | Forklift operator | 4 | 42.2 (5.1) | 18.5 (3.9) |

| Carrier of explosives | 19 | 42.6 (3.1) | 20.1 (5.7) | Excavation workers | 32 | 40.7 (6.3) | 17.2 (7.3) |

| Truck driver | 30 | 45.7 (3.4) | 22.4 (3.9) | Total | 763 | ||

JSA was used to identify hazards of the studied jobs. After identifying jobs with most hazards, occupational risk levels were assessed using the FMEA technique.

JSA: JSA should be performed by a team; thus, a team consisting of a supervisor, an experienced worker, and a safety and health expert was formed to implement this technique to identify and evaluate risks of each job. For the purpose of analysis, each task was broken down into successive steps. Next, different tasks of jobs were identified. At the next stage, hazards of each task of the jobs were identified. Besides, all equipment and machinery, job steps, production processes, and workplace conditions were identified, and risk factors were examined [19, 20].

FMEA: Significant hazards identified in the previous step were assessed in this step. Next, hazards of the environment were assessed using the FMEA method. Besides, the risk priority number (RPN) was calculated using Formula. 1 as follows:

Formula 1.

RPN = S × O × D Eq. 1

Where S, O, and D represent severity, occurrence, and detection, respectively.

Given that the three factors mentioned above could have ranks between 1 and 10, the RPN would be between 1 and 1,000. Large RPNs indicated greater risks. Besides, for large RPNs,

the assessment team would have to take appropriate corrective actions to reduce them, and regardless of the outcome of the RPN, special attention had to be paid to risks of high severity. At this stage, the risks were ranked based on their RPN. Upon determining priorities for selecting defects, it was possible to provide solutions to prevent their occurrence. In the next step, the risks were ranked based on the risk priority number [21]. Based on the FMEA team's opinion, acceptable risk levels were determined. In this project, the reliability coefficient of 90% was obtained for risk control as follows:

Formula 2.

100 × 90% = 900

1,000 – 900 = 100

Accordingly, risks with an RPN below 100 were considered acceptable, and those with an RPN over 100 were considered significant and unacceptable. Besides, risks with an RPN below 70 were considered partial, and those with an RPN within range 70-100 were considered acceptable [22].

Results

As Fig. 1 shows, mechanical repairmen had the highest risk (33 hazards), yet loader operators, topographers, and industrial electricians had the lowest risk (9 hazards).

JSA: JSA should be performed by a team; thus, a team consisting of a supervisor, an experienced worker, and a safety and health expert was formed to implement this technique to identify and evaluate risks of each job. For the purpose of analysis, each task was broken down into successive steps. Next, different tasks of jobs were identified. At the next stage, hazards of each task of the jobs were identified. Besides, all equipment and machinery, job steps, production processes, and workplace conditions were identified, and risk factors were examined [19, 20].

FMEA: Significant hazards identified in the previous step were assessed in this step. Next, hazards of the environment were assessed using the FMEA method. Besides, the risk priority number (RPN) was calculated using Formula. 1 as follows:

Formula 1.

RPN = S × O × D Eq. 1

Where S, O, and D represent severity, occurrence, and detection, respectively.

Given that the three factors mentioned above could have ranks between 1 and 10, the RPN would be between 1 and 1,000. Large RPNs indicated greater risks. Besides, for large RPNs,

the assessment team would have to take appropriate corrective actions to reduce them, and regardless of the outcome of the RPN, special attention had to be paid to risks of high severity. At this stage, the risks were ranked based on their RPN. Upon determining priorities for selecting defects, it was possible to provide solutions to prevent their occurrence. In the next step, the risks were ranked based on the risk priority number [21]. Based on the FMEA team's opinion, acceptable risk levels were determined. In this project, the reliability coefficient of 90% was obtained for risk control as follows:

Formula 2.

100 × 90% = 900

1,000 – 900 = 100

Accordingly, risks with an RPN below 100 were considered acceptable, and those with an RPN over 100 were considered significant and unacceptable. Besides, risks with an RPN below 70 were considered partial, and those with an RPN within range 70-100 were considered acceptable [22].

Results

As Fig. 1 shows, mechanical repairmen had the highest risk (33 hazards), yet loader operators, topographers, and industrial electricians had the lowest risk (9 hazards).

Fig. 1. Hazards identified in the JSA method for different jobs

Fig. 2 shows hazards identified in different jobs by the JSA method. As it can be seen, the throwing or falling of objects on workers (13.93%), slipping and falling from heights (12.61%), and vehicle accidents (11.19 %) had the highest frequency of hazards as identified by the JSA method, respectively.

Fig. 2. Frequency of hazards identified by the JSA method

Table 2 shows the results of FMEA for each job, with the task of the largest number of hazards identified in JSA. Due to the large number of occupations, only occupations with over 20 identified hazards were presented in detail (Table 2). Fig. 3 shows RPNs of all jobs before and after control suggestions were made. As it can be seen, RPNs decreased after applying control suggestions. In addition, all jobs had high risk levels. Accordingly, the risks of dump truck operators, service workers, welders, explosive personnel, kitchen staff, car electricians, industrial electricians, excavation workers, shavel operators, lathe operators, puncture personnel, forklift operators, truck drivers, topographers, and carwash personnel decreased to a low level (partial); however, the risks of mechanical repairmen, excavator operators, operations and repair supervisors, loader operators, warehouse keepers, and explosive carriers decreased to a medium level (acceptable).

Table 2. Risk assessment of high-risk jobs in mine no. 1 of Golgohar Industrial Mining Company in Sirjan

| Job | Process step / input | Potential failure mode | Potential failure effects | Potential causes | S | O | D | Primary RPN | Control suggestions | S | O | D | Secondary RPN |

| Excavator | Unlocking balance jacks | Immersing the balance jacks in the mud | Property damage | Placement of the device on sloping surfaces and excessive soil moisture | 6 | 7 | 3 | 126 | Ensuring correct operation of the power and fuel system, stopping the car 50 m away from the warehouse | 4 | 5 | 3 | 60 |

| Dump truck operator | Going down the ramp | Cutting the wheel and detaching and overturning it from the machine | Severe financial and human losses | Rot in wheel joints, loose joints | 8 | 3 | 6 | 144 | Proper inspection and control of equipment, training, supervision and maintenance | 8 | 2 | 4 | 64 |

| Shavel operator | Lowering the bucket (hoist) | Sudden descending of hoys during rotation | Severe financial and human losses | Drum brake not adjusted, sudden tripping if the pads are not adjusted | 9 | 7 | 6 | 378 | Proper inspection and control of equipment, training, supervision and maintenance | 7 | 3 | 4 | 74 |

| Lathe operator | Shaping or scraping surfaces of metal parts with a milling machine | Workers' hand being pulled towards the cutting plate | Injuries and amputation | Inattention to doing the work and entering clothes to the biting points of the machine, inappropriate clothes of the operator | 7 | 7 | 4 | 196 | Working carefully, proper clothing, and training | 5 | 5 | 3 | 75 |

| Truck driver | Reaching the loading location | Crashing with people and vehicles waiting in line | Financial and human losses | Irregularities, not keeping proper distance from the place of loading | 10 | 5 | 4 | 200 | Training and developing safe work instructions, appointing a safety officer | 10 | 3 | 2 | 60 |

| Welder | Heating and radiating the drilling machine rod | Falling from a height | Injuries, fractures, and death | Lack of personal protective work equipment at heights, imbalance | 9 | 6 | 4 | 216 | Training and compiling safe work instructions and obtaining a hot work permit | 7 | 4 | 3 | 84 |

| Mechanic repairman | Charging auxiliary gas and the coulometer | Fire | Financial and human losses | Non-separation of oxygen capsule storage space from nitrogen capsules | 10 | 6 | 6 | 360 | Separating capsules from each other, using necessary signs and warnings, training, developing occupational safety instructions | 7 | 5 | 4 | 140 |

According to the results, 59% of the identified risks had a high risk level, 35% had a medium risk level, and 6% had a low risk level. After applying control suggestions, 4% of the identified risks had a high risk level, 30% had a medium risk level, and 66% had a low risk level.

Fig. 3. RPNs of the studied jobs before and after the intervention

Discussion

According to Rison's study, unlike obvious errors (especially human errors), latent conditions can be identified and corrected before unfortunate events occur. Understanding this theory facilitates error detection on the way to prospective risk management instead of retrospective risk management [23]. In this regard, hazards in different jobs of the mine were identified by JSA, and their risk level was calculated using FMEA as mentioned earlier; in addition, RPN 100 was considered as the acceptable risk criterion.

As expected, all mining jobs had high and unacceptable risks. The highest number of risks was related to mechanical repairmen, and the lowest numbers of risks were related to loader operators, topographers, and industrial electricians. According to the results, before applying control suggestions, the occupational group of industrial electricians and car electricians had the highest and lowest risk priority numbers, respectively. In addition, after applying control suggestions, loader operators and lathe operators had the highest and lowest risk priority numbers, respectively. In line with the results of the present study, Koohnavard et al reported that the majority of identified hazards were observed in the mechanical unit of Iran Khodro Company [24]. In the study of Permana et al, risk assessment was performed, in which the major source of mine accidents was found to be tools, and the major mine accident locations were the mechanic’s workshop and the mine pit [25]. Based on Onder’s study, the largest proportion of accidents causing injuries occurred by mining machines (39.2%), and other reasons were general machinery (25%), manual and mechanical handling (16.7%), hand tools (11.9%), and getting hit by or falling of objects (7.2%). Besides, maintenance personnel (79.4%) were more likely to get injured than workers (11.7%) and drivers (8.9%) [26].

Based on JSA results, the throwing and falling of objects, slipping and falling from heights, vehicle accidents, as well as dust inhalation and pollution were the most likely hazards in the mine studied. Consistent with the present study, in the study of Ebrahimzadeh et al (2015), rock falls were identified as the major hazard in a uranium mine [27]. Rudakov stated that despite the general desire for reducing the number of fatal injuries among miners, the method of assessing the risk of rock falls needs to be improved, with this problem in mines being always one of the most likely accidents [28]. Work accidents, when conducting mining activities, often occur due to unsafe field conditions. In open mine areas, there is often a slump due to unstable slopes, which can disrupt the activities and productivity of mining companies, thereby causing the falling of workers or objects [29]. Munirwansyah et al showed that slopes in open pit mines require careful engineering to reduce accident potentials [29]. However, the results of a review study by Duarte et al showed that trucks, dump trucks, and conveyors were devices with greatest impacts on accident rates in mines [30].

Exposure to airborne contaminants in the mining process can lead to pulmonary and respiratory disorders among miners [31-33]. In an epidemiological study, production of large amounts of airborne dust during mining operations was known to increase the mortality rate due to lung cancer among the population of suburban residents [34]. In the study of Safinejad et al, exposure of workers at the Sirjan Golgohar iron ore mine to dust and insoluble iron compounds exceeded the recommended standard (5 mg/m3) set by the Center for Environmental and Occupational Health of Iran and ACGIH [35]. In the study of Gholami et al on airborne dust at Sangan mine in Khaf City, concentrated inhalable dust was reported to be more than the recommended standard [36]. Inconsistent with the present study, studies in the United States and Sweden reported that the rate of dust inhalation in iron mines was satisfactorily low due to the availability of optimal industrial ventilation systems [37, 38]. Biological monitoring, as the best way for assessing occupational exposure, has in recent years attracted the attention of many researchers and has been considered an alternative for comparing the level of exposure of individuals, according to occupational standards [39, 40].

Heavy machinery is considered one of the major contributors to accidents in this industry [30]. Given high work demands, work pace control, and heavy workloads, operators do not have enough knowledge and ignore safety [41, 42]. Failure to fasten seatbelts was associated with several loader and truck accidents [43]. Being inattentive to safe working procedures or standard operating procedures, as well as unsafe or careless actions could be the cause of work-related accidents [25]. In addition, failure to recognize adverse geological conditions, respect the loader’s working area, and maintain adequate berms, as well as the lack of warning signs and appropriate mine maps, inadequate provision of safety levels, and failure to adapt to poor weather conditions were all worker behaviors posing a significant threat [44]. Losing control of equipment has been reported as the leading cause of machine-related fatalities in surface mining [45]. Based on some studies, occupational groups having the highest percentage of all accidents in mines were maintenance personnel and mechanic repairmen [26, 46, 47]. Groves et al [48] showed that a significant portion (54%) of accidents in the mining industry was due to material handling, machinery (12%), hand tools (11%), roof falls (10%), and powered haulage (8%).

In this study, high risk levels accounted for 59% of all identified risks that needed to be corrected immediately, and 35% of the identified risks had moderate risk levels that needed to be reduced. After the interventions, the risks identified at high and medium levels were 4 and 30%, respectively, which indicated the positive effect of the suggestions on reducing risk levels of the studied jobs. Based on the literature review, the types of activities most often associated with injuries in mining had not changed much. In addition, despite various realities in different countries studied, the number of accidents was higher than expectations. Equipment contributing most to work-related accidents included haul trucks, dumpers, and conveyors, especially during maintenance operations.

The limitation of the present study was that it was done on one mine, so it is suggested to be repeated in similar mines and other mines of Golgohar Company.

Conclusion

In this study, high-risk jobs and significant work-related hazards were identified in a mine. As can be seen, control suggestions, such as improving safe operation conditions, training workers, and using protective equipment were able to reduce hazards in all jobs. Constant identification and control of mining hazards should be considered necessary measures for preventing accidents as well as monitoring and controlling equipment operations effectively. In addition, compliance with rules and regulations should be coincided with training and education, with special attention to be given to less experienced workers who are more vulnerable to equipment-related accidents. Besides, educational programs should include ergonomics of carrying objects manually, careful use of hand tools, and importance of using personal protective equipment. Furthermore, factors, such as training and competence assurance management of fatigue-induced errors as well as control of workloads could eliminate some errors leading to accidents. Additionally, manufacturers should improve equipment safety and protective devices at some entry points to protect workers from getting caught in or rolled up in machinery during operations. Careful job planning and effective communication about tasks could help avoid most accidents.

Acknowledgement

The authors would like to extend their thanks to all participants for their support and assistance. They would also like to thank Sirjan School of Medical Sciences for supporting this project (No. 20834).

Conflict of interest: None declared.

References

1. 1. Mohammadfam I, Neazamodini Z. Effect of Technical Intervention in Promoting Safety Culture Assessment. Jundishapur J Health Sci 2010; 2(3):66-74. [Article]

2. 2. Gholi Pour M, Feyzi V, Khammar A. Identification and Assessment of Dangers' Risk in Production Hall of Radiator Parts a Metal Industry with JSA Method. J Occup Hyg Health Promot 2017; 1(1): 42-51. [Article]

3. 3. Unsar S, Sut N. General assessment of the occupational accidents that occurred in Turkey between the years 2000 and 2005. Saf Sci 2009; 47(5):614-9. [DOI]

4. 4. Mikaeil R, Jafarpour A, Hoboubeh A. Safety risk analysis of dimensional stone quarried by diamond wire saws using FMEA method (Case study: Badeki marble quarry - Ghareh-Ziaeddin). J Miner Resour Eng 2017; 2(1):75-84. [Article]

5. 5. Zare A, Yazdani Rad S, Dehghani F, Omidi F, Mohammadfam I. Assessment and analysis of studies related human error in Iran: A systematic review. J Health Saf Work 2017; 7(3):267-78. [Article]

6. 6. Md-Nor ZA, Kecojevic V, Komijenovic D, Groves W. Risk assessment for haul truck-related fatalities in mining. Min Eng 2008; 60(3):43-9.

7. 7. Hasanzadeh L, Khani Jazani R, Gholamnia R, Monazami Tehrani G. Development a Questionnaire to Assess the Work Related Accidents in Open Pit Metal Mines According to Rules and Regulations. Saf Promot Inj Prev 2018; 6(4):203-14. [DOI]

8. 8. Javadi M, Saeedi G, Shahriar K. Prioritizing of hazars in mechanized longwall coal mining: a case study of Tabas Coal Mine. J Anal Numer Methods Min Eng 2016; 6(11):39-51 [Article]

9. 9. Zhang Y, Shao W, Zhang M, Li H, Yin S, Xu Y. Analysis 320 coal mine accidents using structural equation modeling with unsafe conditions of the rules and regulations as exogenous variables. Accid Anal Prev 2016; 92:189-201. [DOI] [PMID]

10. 10. Yari S, Fallah Asadi A, Varmazyar S. Assessment of Semi-Quantitative Health Risks of Exposure to Harmful Chemical Agents in the Context of Carcinogenesis in the Latex Glove Manufacturing Industry. Asian Pac J Cancer Prev 2015; 17(S3):205-11. [DOI] [PMID]

11. 11. Yari S. Assessment of potential risk by the failure mode and effects analysis in an air conditioning equipment manufacturing company. Safe Promot Inj Prev 2017; 5(2):89-96. [DOI]

12. 12. Ghahremani A, Adl J, Nasl-Seraji J. Process Equipment Failure Mode Analysis in a Chemical Industry. Iran Occup Health J 2008; 5(1-2):31-8. [Article]

13. 13. Gueorguiev T, Kokalarov M, Sakakushev B. Recent Trends in FMEA Methodology. Paper presented at: The 7th International Conference on Energy Efficiency and Agricultural Engineering (EE&AE); 2020 Nov 12-14; Ruse, Bulgaria.

14. 14. Mollazadeh N, Mosavi SM. Safety and Environmental Risk Assessment via FMEA Method in NEWPIPE Company Research Subject. J Environ Sci Stud 2019; 4(3):1572-81. [Article]

15. 15. Oldenhof MT, van Leeuwen JF, Nauta MJ, de Kaste D, Odekerken-Rombouts YM, Vredenbregt MJ, et al. Consistency of FMEA used in the validation of analytical procedures. J Pharm Biomed Anal 2011; 54(3):592-5. [DOI] [PMID]

16. 16. Alimohammadi I, Adl J. The comparison of safety level in kilns in two gypsum production factories by Failure Modes and Effects Analysis (FMEA). Iran Occup Health J 2008; 5(1-2):77-83. [Article]

17. 17. McDermott RE, Beauregard MR, Mikulak RJ. Methods of Failure Mode Effect Analysis (FMEA). [M. Noshad Haghighi, Trans]. 1st ed. Tehran: Sapco Pub: 2000.

18. 18. Yousefi Aghkand M, Farshad AA, Arghami SH. Evaluation & Identification of Hazards for Employees in Oil Exploration Seismic Operations with Job Safety Analysis Method. Iran Occup Health J 2007; 3(3-4):39-45.

19. 19. Jaddi Madarsara T, Yari S, Saeidabadi H. Health and Safety Risk Assessment Using a Combined FMEA and JSA Method in a Manufacturing Company. Asian Pac J Environ Cancer 2019; 2(1):63-8. [DOI]

20. 20. Rasoulzadeh, Y, Alizadeh SS, Valizadeh S, Fakharian H, Varmazyar S. Health, Safety and Ergonomically Risk Assessment of Mechanicians Using Job Safety Analysis (JSA) Technique in an Iran City. Indian J Sci Technol 2015; 8(28). Doi: 10.17485/ijst/2015/v8i28/83377. [DOI]

21. 21. Yang Z, Wang J. Use of fuzzy risk assessment in FMEA of offshore engineering systems. Ocean Eng 2015; 95:195-204 [DOI]

22. 22. Safari H, Faraji Z, Majidian S. Identifying and evaluating enterprise architecture risks using FMEA and fuzzy VIKOR. J Intell Manuf 2016; 27(2):475-86 [DOI]

23. 23. Reason J. Human error: models and management. BMJ 2000; 320(7237):768-70. [DOI] [PMID] [PMCID]

24. 24. Kouhnavard B, Aghanasab M, Safayee R, FazlI Z. Risk Identification and Assessment, Using Job Safety Analysis, in an Affiliated Agencyto Iran Khodro Company, 2014. Beyhagh, J Stud Res Committee 2015; 20(3):40-50. [Article]

25. 25. Permana H. Risk Assessment as a Strategy to Prevent of Mine Accidents in Indonesian Mining. Min Rev 2012; 18(4):43-9.

26. 26. Onder S. Evaluation of occupational injuries with lost days among opencast coal mine workers through logistic regression models. Saf Sci 2013; 59:86-92. [DOI]

27. 27. Ebrahimzadih M, Halvani GH, Darvishi E, Froghinasab F. Application of Job Safety Analysis and William Fine Methods to Identify and Control Hazards in a Uranium Mine in Central Area of Iran. J Health 2015; 6(3):313-24. [Article]

28. 28. Rudakov ML, Kolvakh KA, Derkach IV. Assessment of Environmental and Occupational Safety in Mining Industry during Underground Coal Mining. J Environ Manag Tour 2020; 11(3):579-88. [DOI]

29. 29. Munirwansyah, Irsyam M, Munirwan RP, Yunita H, Zulfan Usrina M. Geotechnical Approach for Occupational Safety Risk Analysis of Critical Slope in Open Pit Mining as Implication for Earthquake Hazard. Mater Sci Eng 2018; 352:012035. [DOI]

30. 30. Duarte J, Baptista JS, Torres Marques A. Occupational Accidents in the Mining Industry—A Short Review. In: Arezes PM, Baptista JS, Barroso MP, Carneiro P, Cordeiro P, Costa N, et al (eds), Occupational and Environmental Safety and Health. Switzerland AG: Springer, Cham; 2019. (Studies in Systems, Decision and Control, Vol 202). [DOI]

31. 31. Ädelroth E, Hedlund U, Blomberg A, Helleday R, Ledin MC, Levin JO, et al. Airway inflammation in iron ore miners exposed to dust and diesel exhaust. Eur Respir J 2006; 27(4):714-9. [DOI] [PubMed]

32. 32. McIvor A, Johnston R. Miners' Lung: A History of Dust Disease in British Coal Mining. 1st ed. London: Routledge; 2016. [DOI]

33. 33. Majdi M, Rafeemanesh E, Ehteshamfa SM, Fahool MJ, Masoodi S. Analyzing occupational lung disease among turquoise miners. Iran Occup Health J 2009; 6(2):31-7. [Article]

34. 34. Crosby L, Tatu C, Charles K. Lung and Bronchus Cancer Deaths in Boone County, Wv Before and After Mountaintop Removal Mining. J Rare Disord: Diagn Ther 2016; 2(1). doi:10.21767/2380-7245.100035 [Article]

35. 35. Safinejad M, Azari MR, Zendehdel R, Rafieepour A, Khodakarim S, Khodarahmi B. Occupational and biological monitoring of workers exposed to airborne dust in Gol-e-Gohar Iron Ore mine: A Case-Control Study. Iran Occup Health J 2019; 16(1):23-32. [Article]

36. 36. Gholami A, Fani MJ, Sadeghi N. Occupational Exposure Determination to Silica Dust in an Iron-Stone Ore and Comparison with Standard. Int J Collab Res Intern Med Public Health 2012; 4(6):1141-9. [Article]

37. 37. Hwang J. Assessing present-day and historical exposures of workers to taconite dust in the iron mining industry in northeastern Minnesota [PhD thesis]. Minnesota, United States: University of Minnesota; 2013. [Thesis]

38. 38. Adelroth E, Hedlund U, Blomberg A, Helleday R, Ledin MC, Levin JO, et al. Airway inflammation in iron ore miners exposed to dust and diesel exhaust. Eur Respir J 2006; 27(4):714-9 [DOI] [PMID]

39. 39. Hassani H, Golbabaei F, Shirkhanloo H. Manganese-Iron Ratio (MIR) as a potential biomarker for manganese exposure assessment. Iran Occup Health J 2016; 13(3):47-53. [Article]

40. 40. Asadi P, Azari MR, Rafieepour A, Rahmati A. Feasibility of Biological Monitoring of Anatomy Laboratory Staff Exposed to Formaldehyde. Health Scope 2018; 7(4):e62470. [DOI]

41. 41. Amponsah-Tawiah K, Jain A, Leka S, Hollis D, Cox T. Examining psychosocial and physical hazards in the Ghanaian mining industry and their implications for employees’ safety experience. J Saf Res 2013; 45:75-84. [DOI] [PMID]

42. 42. Nasarwanji MF, Pollard J, Porter W. An analysis of injuries to front-end loader operators during ingress and egress. Int J Ind Ergon 2018; 65:48-92. [DOI] [PMID] [PMCID]

43. 43. Kecojevic V, Komljenovic D, Groves W, Radomsky M. An analysis of equipment-related fatal accidents in U.S. mining operations: 1995-2005. Saf Sci 2007; 45(8):864-74. [DOI]

44. 44. Zhang M, Kecojevic V, Komljenovic D. Investigation of haul truck-related fatal accidents in surface mining using fault tree analysis. Saf Sci 2014; 65:106-17. [DOI]

45. 45. Ruff T, Coleman P, Martini L. Machine-related injuries in the US mining industry and priorities for safety research. Int J Inj Contr Saf Promot 2011; 18(1):11-20. [DOI] [PMID]

46. 46. Burgess-Limerick R. Injuries Associated with Underground Coal Mining Equipment in Australia. Ergon Open J 2011; 4(1):62-73. [DOI]

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution 4.0 International License. |